Swapping an engine into any modern car is not without it’s challenges. "Panhard", the affectionally named Toyota 86, has had its stock FA20 engine swapped out for a 4 litre 1UZFE VVTi Toyota V8, which will be an exciting fix for the 86’s much lamented lack of power. In this multi-part series you will learn what it takes to overcome the challenges as we take you through the planning, motorsport wiring, engine ECU configuration and dyno tuning processes. We will show you everything that's needed to take the car from a lifeless garage ornament, to a powerful, exciting, and reliable weapon.

To make it easier to work on we've put the 86 up on axle stands. This puts the car at a convenient working height and allows us to easily complete any work under the car. We even cleaned up the workshop a bit while we were at .

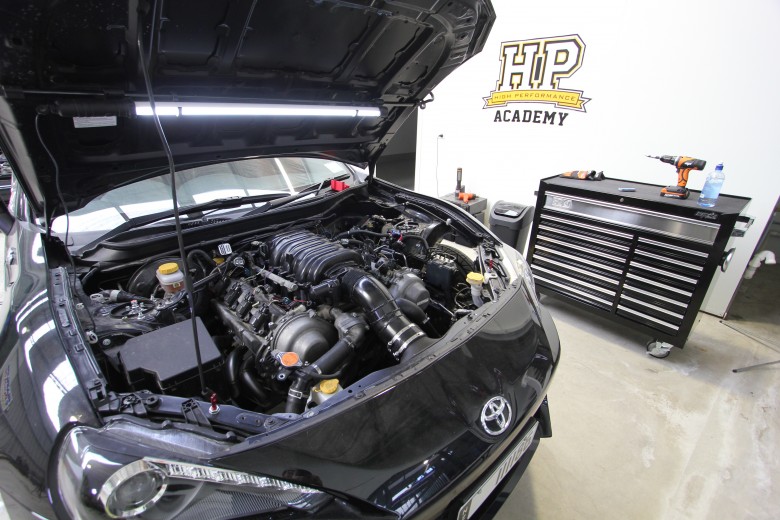

The Toyota 1UZFE looks great in the engine bay. It almost looks like it was meant to be. Notice the LS2 drive by wire throttle body that has replaced the factory unit.

We've chosen a MoTeC M150 ECU equipped with MoTeC's Toyota 86 Package which has been specifically designed to control the Toyota 86, including replicating all the CAN communication.

The MoTeC M150 86 Package also includes an adaptor harness that goes between the ECU and the stock wiring harness inside the car which makes the installation at ECU-end very simple. If we still had the factory engine then our job would be done, but in our case we need to adapt the wiring to the new engine.

To keep costs down, rather than creating a complete new harness we’re simply making a new engine harness from the factory bulkhead connector to suit the new V8 engine. Pictured above is the factory FA20 engine loom connector. Because the 4 cylinder FA20 is quite a complex engine, there are enough pins on this plug that we can re-allocate to run the 8 cylinder 1UZFE engine.

The MoTeC LTC, or 'Lambda To CAN' module, enables us to input information from a wideband oxygen sensor in each bank of the exhaust. This will help with tuning by letting us see air fuel ratio information on the laptop and also lets us use MoTeC's 'Quick Lambda' function to automatically tune the fuel table. Having AFR information will also let us setup closed loop fuel control for accurate mixture control once it leaves the dyno.

Pressure sensors for both fuel and oil will be installed and wired to the ECU. This will give us the ability to setup engine protection strategies to prevent damage in case something goes wrong.

Stay tuned for the next stage in this build where we wii go through the planning process.

Comments

No one has commented on this page yet.