Tuning a naturally aspirated engine is often more challenging than forced induction.

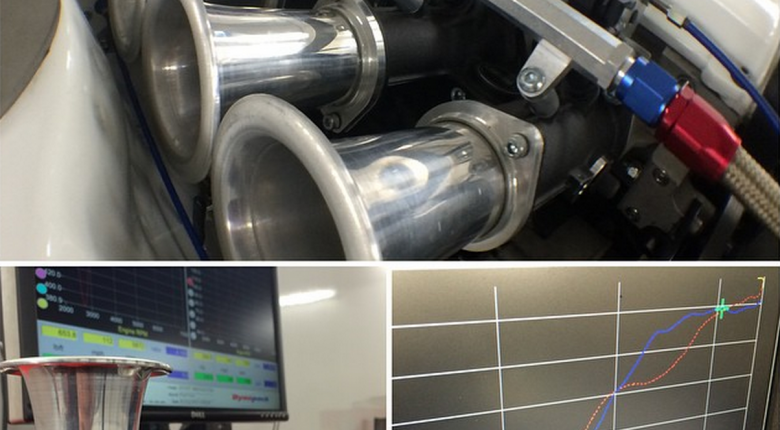

A highly strung n/a engine doesn't have boost pressure to make up for compromises in the engine design so to get the best results everything must be designed to perfection. In this instance tuning the intake trumpet length can have a dramatic effect on both the torque delivery as well as the peak power. Getting the intake runner length just right can take advantage of pressure waves in the runner to aid cylinder filling.

Air is a little like a spring, and when the intake valve closes, the air column comes to a stop and stacks up on itself, compressing near the valve and creating a high pressure area. Just like a spring, this pressure wave then travels back up the intake runner and when it reaches the end of the trumpet it reverses and heads back towards the valve. The trick is getting the trumpet length just right so that the pressure wave reaches the intake valve as it opens again for the next engine cycle. If we get it right, the pressure wave can then be used to help force more air into the cylinder.

This sort of tuning is only effective across a narrow rpm range though, so you need to decide where in the rpm range you want to focus your efforts. As a rough rule, short trumpets promote better high rpm power, while longer trumpets favour low rpm torque. Getting the best compromise involves a lot of accurate dyno testing.