Ripping all your OEM wiring out and starting from scratch is a common wish, but is often seen as a daunting task when it comes to deciding what a 'bare essential wiring' setup looks like.

1 of 36 modules from the full PDM Installation and Configuration course.

Using a street legal track car as the example, Zac runs us through his 'bare essential' wiring list and how the ties into your PDM setup, with a quick note on how your ignition key actually works so you can ensure you wire the right components to the correct pins with a full understanding of why.

NOTE: Our laws might be different, so this is just a guide, not an instruction on what YOU do or don't need legally, and of course if you have a track-dedicated car your rule book is what you should consult regarding requirements, particularly lighting.

WHAT IS A PDM?

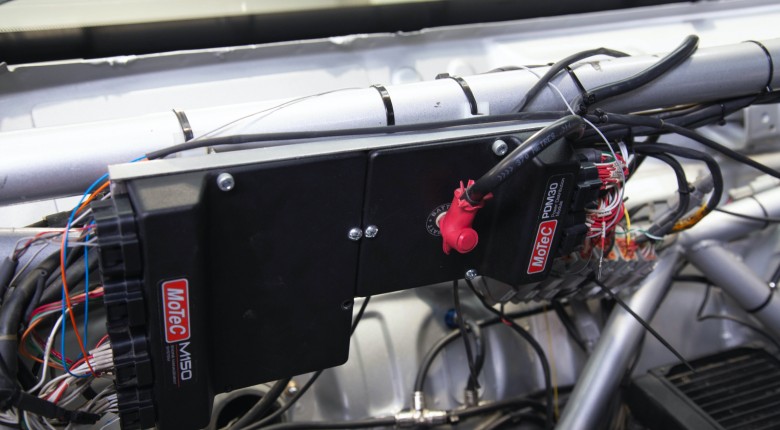

A power distribution module (PDM), power management unit (PMU) and power distribution unit (PDU) are all the same thing with different names, much like how variable cam control is called something different by each other car manufacturer.

Over the last few years, we’ve seen PDMs become more popular and more affordable which means we’re seeing them pop up in more and more cars running at the grassroots level. These units replace the conventional fuses and relays we need to control and protect the various electrical circuits on our car with solid-state electronics to control current flow. This dramatically simplified the wiring installation and can also improve reliability. With a conventional fused circuit, if the current is excessive, the fuse will blow to protect the components and you need to stop and replace the fuse to get going again.

With a PDM, the fusing current can be adjusted in software and the unit will simply shut off the circuit if the fusing current is exceeded. The intelligent part however is that you can then configure the PDM to wait a specific amount of time before retrying the circuit that just failed. You can also set how many times the unit will retry before failing permanently. This is often enough to nurse a car with a failing electrical part back to the pits for repair. It’s also possible to log and display the current draw on each circuit so you can see exactly what’s going on with every part of the electrical system.

At this point, a PDM is still going to end up more expensive than using fuses and relays but when weighing up options, most enthusiasts overlook the cost involved with mounting and wiring the relays and fuses. When you factor that in, upgrading to a PDM often isn’t going to cost substantially more and by the time you consider the advantages, it can start to look pretty attractive.

------------------------------------

TIME STAMPS

0:00 - Minimal Wiring: Theoretical Situation

1:37 - Device Example List

2:27 - Sensors - ECU Is Separate

2:53 - Current Draw - Generic Values

11:37 - PMU/PDM Inputs & Control Functions

12:15 - [SIDE NOTE] Ignition Operation

17:00 - Back To Inputs & Control Functions

17:25 - Starter Solenoid

17:29 - Fuel Pump & Cooling Fans

17:50 - CAN Bus Communications

18:13 - Lighting - Indicators, Hazard, Dip and Full, Brake, Reverse, License Plate

22:07 - 'And' Function Usage

23:02 - Wiper, Washer and Horn

23:42 - Hope This Helps!

24:02 - Link Below (Lies! It's above)

24:15 - Just A Small Bit Of Knowledge From A Full PDM Course

Comments

No one has commented on this page yet.