It doesn’t matter what level you’re racing at, the contact patch between your wheels and the race track are going to determine how fast you can go, and a wheel alignment is essential to optimise this.

James Stevens of Jota Sport runs us through some of the techniques and equipment used in the upper echelons of motorsport, specifically on their 930kg, 4.2-litre V8 N/A, X-Trac 6-speed sequential ORECA LMP2 race car in this [TECH TALK].

A JOTA Sport team car has finished 1st or 2nd in LMP2 at Le Mans 8 times in the last 8 years using this knowledge which is certainly a feat that doesn't happen by chance.

Setting the car up starts in the workshop, and Jota Sport use a perfectly flat and level steel plate that is checked yearly and used to ensure accuracy and consistency in many aspects of the cars setup. Corner weights and camber gauges are zeroed according to this, and checked often so that when traveling abroad the team can get as close as possible to a flat surface to work from as possible with a small margin of tolerance allowed and factored into any adjustments the car needs.

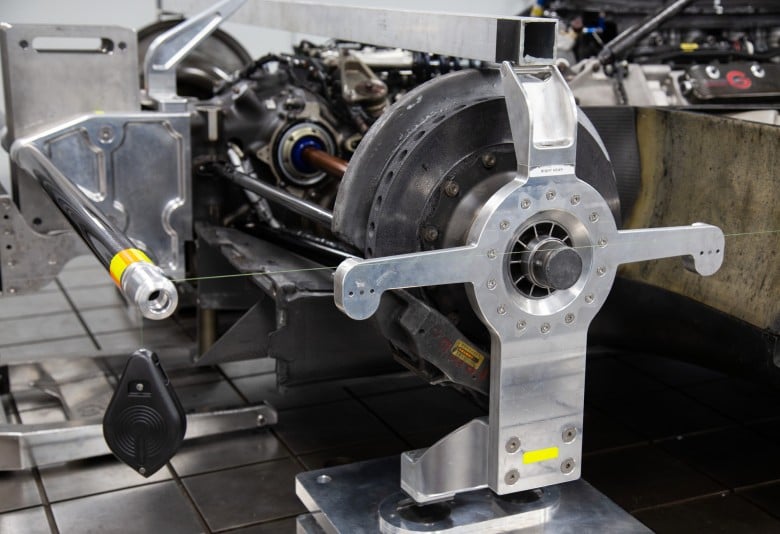

Steel plates are also used instead of rims and tyres when doing the alignment to remove an extra layer of inconsistencies particularly since that car will run multiple rims and tyres throughout just a single event. Interestingly a string alignment setup similar to what you would use on your own road/track car is used at both the workshop and the track with it being preferred over laser alignment systems not because of cost, but because of complexity drawbacks and the ease of travel.

The ultimate goal and focus of a dedicated race car like the ORECA LMP2 is always peak performance rather than creature comforts and aesthetics like a road car also considers more in depth, and as such a 1kg difference is allowed across the front and less than 10kg across the rear to ensure even weight distribution and consistent brake performance. There is no minimum ride height for the car, but instead 25mm skids are fitted which the teams can wear 5mm off during the course of an event, but if any more is measured to be missing the car will be disqualified from the event and as such the height will be adjusted from track to track just as the camber and toe etc is.

Once the car is setup for the track, spares such as the track arms, push rods and camber shims are also set to match so that in the event a corner of the car is damaged the team can quickly replace everything required knowing the correct setup remains enabling the driver to keep confidence the cars handling.

Interested in learning how to do your own wheel alignment for the track or street? Start with a free alignment & suspension 101 lesson now.

Comments

No one has commented on this page yet.