We've posted an article which covered some of the advantages of E85 over normal pump fuel. It’s a great fuel for the performance enthusiast, but what if you don’t have a ready supply of E85 at the pump in your part of the world?

Well we can take note of how the OEMs do it with the Flex Fuel vehicles that are available in some markets. Flex Fuel vehicles give you the ability to fill up at the pump on normal gasoline, E85, or any mixture in between and the ECU can adjust the tune to suit.

To allow this to work, the ECU needs to know the fuel composition, or what percentage of ethanol is in the fuel. This information is supplied by an ethanol content or fuel composition sensor. The fuel composition sensor is basically a cylindrical capacitor that comprises of two tubes which the fuel flows through as its electrodes. The basis of the sensor’s operation is that the permittivity of the fuel, and hence capacitance, changes with ethanol content. An AC voltage is applied to the electrodes and as the capacitance increases, the oscillation frequency of the system will change and a microprocessor determines the capacitance from this measured frequency. The fuel temperature sensor is required since the permittivity of ethanol fluctuates with temperature as well as ethanol content and hence this must be accounted for to ensure accuracy. Once the ethanol content has been determined, this and the fuel temperature are output to the ECU as a digital signal.

While not strictly necessary for flex fuel operation, fuel temperature affects the density of the fuel and hence this input can also be used by the ECU to maintain a more accurate control of the air fuel ratio as fuel temperature changes. The output of the sensor is quite unique as both pieces of information are sent via a single digital signal. The frequency (number of waves per second), and the pulse width (how long the signal is in the high state) are used to tell the ECU what’s happening.

Here you can see the sensor readings displayed on the dash. EC is the ethanol content (in this case 80%) while FT is the fuel temp (currently sitting at 46 degrees)

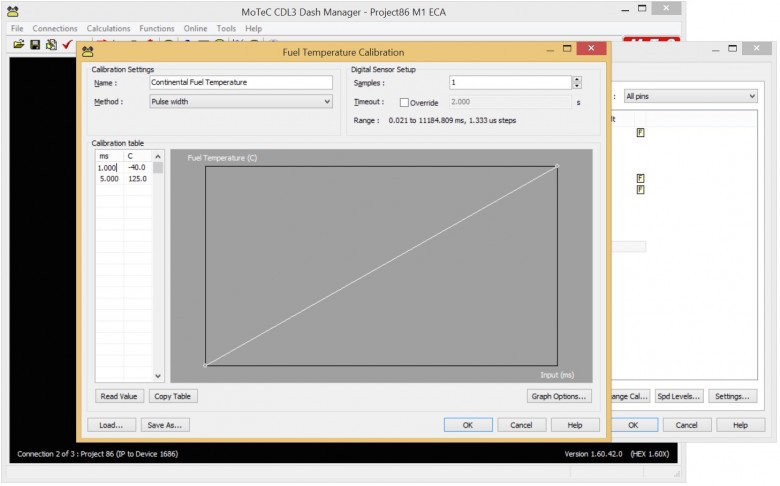

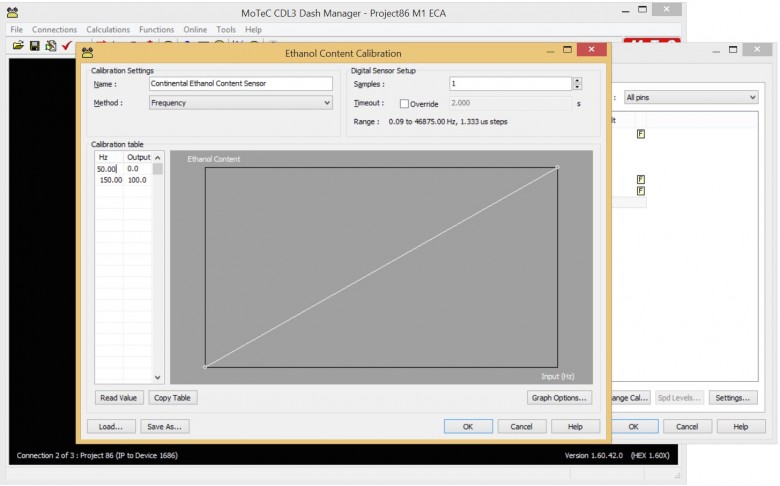

With the Continental fuel composition sensor pictured, the frequency varies between 50 Hz which represents E0 (0% ethanol) and 150 Hz which represents E100, and at the same time a pulse width of 1 millisecond represents a fuel temperature of -40 degrees C and a pulse width of 5 milliseconds represents a temperature of 125 degrees C. This information can then be decoded by the ECU to allow it to optimise the fuel and ignition delivery based on the current ethanol content.

How the ECU deals with ethanol content will depend on the manufacturer, however at a minimum the ECU will alter the fuel delivery to maintain the target air fuel ratio. If we want to take advantage of the performance benefits of E85 we could also alter the ignition timing and boost targets based on ethanol content. One of the more time consuming tasks is to alter the cranking and warm up enrichment maps to maintain clean and fast starting on high concentrations of ethanol. Ethanol is much less volatile than gasoline which makes it harder to light off in cold climates.

If you want to learn more about the effect of ethanol, check out our Understanding AFR course.

If you are interested in learning more about tuning, why not begin with our free 'Bare Minimum Tuning Knowledge' course. Did we mention it's free?

Pictured is the Continental ethanol content sensor we fitted to our turbocharged Toyota 86. This sensor needs to be located somewhere in the fuel supply line to the engine so we fitted it to the left passengers strut tower which made it easy to adapt into the fuel plumbing. We chose to use AN adaptors to connect the fuel inlet and outlet.

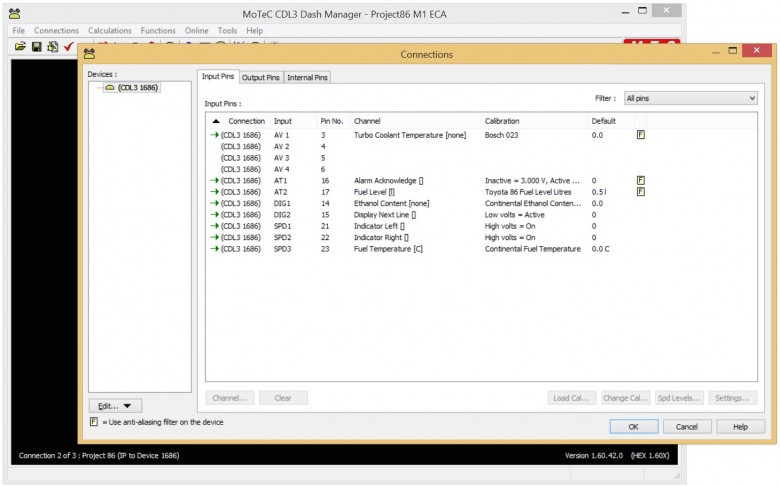

Since our MoTeC M1 currently doesn't offer flex fuel support, we wired the fuel composition sensor into our MoTeC CDL3 dash so we could at least monitor it. The dash offers the option of DIG inputs or SPD inputs and while both will read a digital signal,r when measuring pulse width the DIG input measures the low time while SPD measures the high time. This means to correctly display fuel temp we need to use a SPD input

Here you can see the calibration data for the fuel temperature. This input is a pulse width measurement where a pulse width of 1 milliseconds is equal to a temperature of -40 degrees C, while 5 milliseconds is equal to 125.

This shows the calibration of the ethanol content. This input uses frequency measurement with 50 Hz displaying zero percent ethanol and 150 Hz displaying 100%.

Want to learn more? Check out the full Ethanol and Flex Fuel Training course here.

Comments

- Andre.Simon New Zealand

10 years ago

- Anonymous user United Kingdom

10 years ago

No one has commented on this page yet.