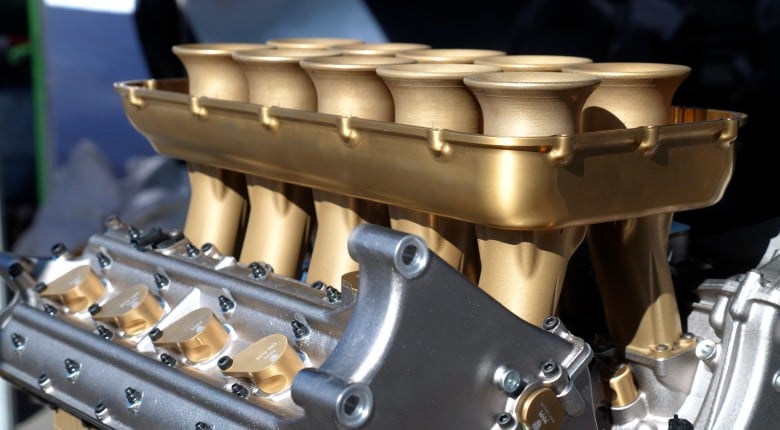

It's unusual to see a new V10 engine go into production these days with the V10 and V12s engines of previous Formula 1, Prototype (LMP) and Grand Touring classes long being replaced by V8s and V6s, but Rodin Cars are bucking the trend with their RC.TEN engine project.

Mike Gartrell of RodinCars runs us through some of the ins and outs of this V10 project, including how partners like Neil Brown Engineering have helped with the design and Pankl Racing Systems with production. However, with low quantity runs costing as much as €45,000 ($49,000 USD) per crank, the long-term plan is to bring the manufacturing in-house to their New Zealand base.

The 2024 World Time Attack Challenge was the first outing and test of the engine as part of the Rodin SINTURA project, a controversial carbon monocoque chassis that has been given an exemption to compete at the event.

RC.TEN Specs:

- 3998cc - (244ci) 72° naturally aspirated V10

- 12,000rpm

- 185bhp/litre

- Cast Aliminium head and block with Nikasil coated steel liners

- 86mm bore, 68.8m stroke

- DOHC

- Bosch direct injection system running 102 RON fuel

- 15:1 compression ratio

- 720bph @ 11,000rpm - N/A goals

- Twin Turbo Capable

- 160kg

- Link G5 ECU & electronics package

------------------------------------

TIME STAMPS:

0:00 - V10 V12 Nostalgia

0:20 - Mike Gartrell: Rodin Cars

0:30 - Why Design A New V10?

1:07 - What Did It Take?

1:58 - Neil Brown Engineering

2:17 - Design Process Simplification

2:30 - Engine Specs

3:05 - Volumetric Efficiency

4:10 - RPM Multiplier

4:28 - In House Machining

5:04 - Why? (Scale)

5:59 - 3D Printing & Casting

6:42 - What Is Vacuum Casting

7:12 - Why Cast Vs CNC Vs 3D Printing

7:48 - Initial Testing

8:26 - Sentura Packaging Restrictions

8:44 - Twin Turbo Plans

9:48 - Steel Lined Bore

10:17 - What Is Nikasil?

10:57 - Direct Injection

11:29 - Bosch Fuel System

12:06 - www.rodincars.com

12:10 - BUILD.TUNE.DRIVE

Comments

No one has commented on this page yet.