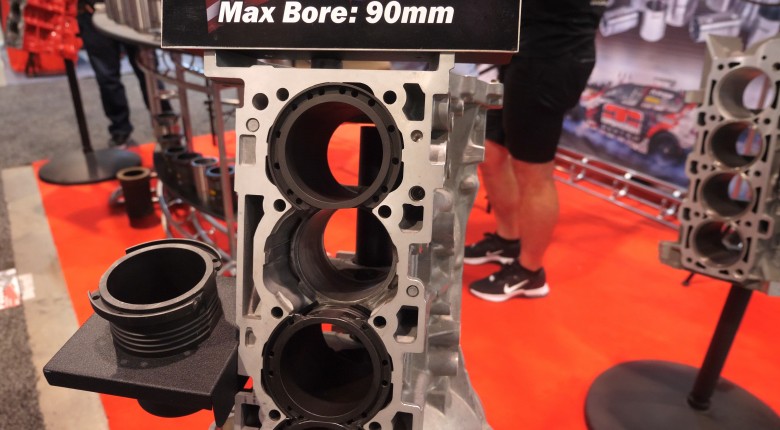

The factory design of engine blocks did not anticipate the extreme boost pressures we see today, often struggling to even handle 15 psi let alone 100 psi or more which many are pushing down the drag strip. Fortunately, there are aftermarket modifications available that allow us to push the limits without the risk of splitting our engine blocks in half.

Modern engine builds now achieve power levels that were unimaginable not long ago, especially in small 4-cylinder applications, with boost pressures exceeding 100 psi. Products like Darton Sleeves have turned this once-unbelievable potential into reality.

John Catapang from @DartonSleeves1 answers our questions regarding the limitations of OEM sleeves and how their MID sleeves and improved fitment have addressed these issues. He also discusses the importance of precision machining and selecting a knowledgeable company, as a bad one certainly won't foot the bill for replacing your entire engine if they overpromise and underdeliver. Make sure to do your due diligence and choose a reputable company capable of delivering repeatable results.

------------------------------------

TIME STAMPS:

0:00 - Too much boost?

0:23 - What the sleeve does.

0:50 - Improving open deck blocks.

1:58 - Sleeve dropping. What is it?

3:00 - Tiny movement = big problems!

3:32 - Cause? Process/fitment issues

4:18 - How do people get it wrong?

5:09 - Are CNC's a requirement?

5:48 - Heat from machining matters.

7:02 - Finding a machinist.

7:41 - Thanks John!

8:09 - BUILD | TUNE | DRIVE

Comments

No one has commented on this page yet.