Ever wondered what the difference between what you do with your crimpers and what those doing wiring work on a bigger scale is and how they maintain quality?

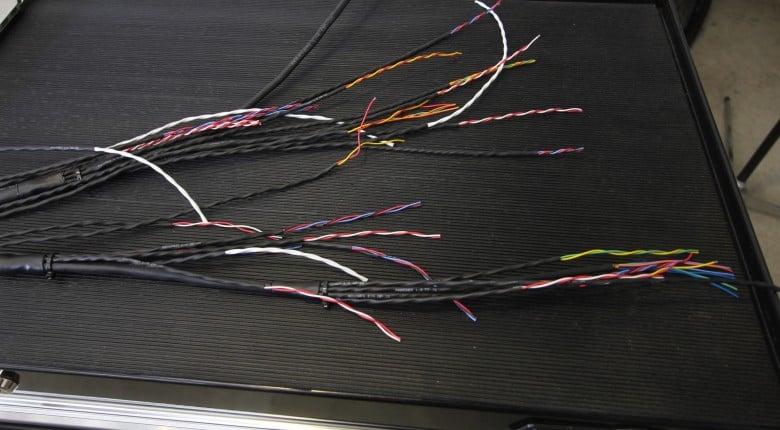

Quality tools and a solid process is the obvious answer, but what does that look like? Ryan Nicholls of Powertune runs us through some of the equipment they use, which enables them to deliver a quality crimp every time without fear of operator fatigue, tooling errors and similar. Interestingly crimping terminals for a Deutsch DTM, AMP Superseal connector or similar, setups like this will work to within 0.01mm of accuracy.

We also gain some insight into why stripping Tefzel wire is harder than lower-quality wire sheathing, although the minor complication is easily managed with appropriate tooling/strippers.

Of course, you can't mention crimping without soldering coming up and there will always be some applications it suits, but it's important to note even with soldering's inherent flaws when you do need to use it there are ways to mitigate the risk. At the end of the day a quality wiring job is about more than just the connection choice alone.

------------------------------------

TIME STAMPS:

0:00 - Crimping Vs Soldering

0:28 - Why Not ALWAYS Crimp By Hand?

0:50 - Quality Control

1:32 - Measure & Strip Tool

2:18 - Stripping Tefzel Wiring

3:25 - Machine Crimping

4:03 - Repeatable Every SINGLE Time

4:09 - Soldering

4:47 - Solder Wicking & Stress Relief

5:19 - Not Cheap, But Interesting!

5:33 - BUILD | TUNE | DRIVE

Comments

No one has commented on this page yet.