One of the most critical factors in designing a wiring harness power supply is ensuring the correct size of the wires providing power to each component. Mistakes in wire sizing can have catastrophic consequences, including overheating, insulation failure, and even fire hazards.

To avoid these issues, it’s essential to ensure that each wire can handle the current drawn by the device it powers without overheating. Overheating can cause the insulation to melt, which increases the risk of fire. The first step is to calculate the current each powered component will draw. This can be done using Ohm’s Law or the power equation, depending on the available information. Once we know the current, we can determine the correct wire size.

Typically, the smallest wire that can safely handle the current is used. This approach minimises cost, weight, and bulk in the wiring loom. However, things get more complex when one power supply wire is spliced to multiple components. For example, a single wire might power all the fuel injectors in a car. In this case, the section of wire before the splice needs to be larger than the wires branching out to individual injectors, as it carries the current for all injectors.

| Copper Conductor Size (Does not include insulation) | ||||

| AWG | Area (mm²) | Diameter (inch) | Diameter (mm) |

Typ Max Current (A)

|

| 24 | 0.21 | 0.0201 | 0.51 | 1.6 |

| 22 | 0.32 | 0.0253 | 0.64 | 2.4 |

| 20 | 0.51 | 0.0320 | 0.81 | 4.0 |

| 18 | 0.79 | 0.0403 | 1.02 | 5.6 |

| 16 | 1.31 | 0.0508 | 1.29 | 8.0 |

| 14 | 2.08 | 0.0641 | 1.63 | 12.0 |

| 12 | 3.30 | 0.0808 | 2.05 | 16.0 |

| 10 | 5.27 | 0.1019 | 2.59 | 24.0 |

| 8 | 8.34 | 0.1285 | 3.26 | 32.0 |

| 4 | 21.0 | 0.2043 | 5.18 | 56.0 |

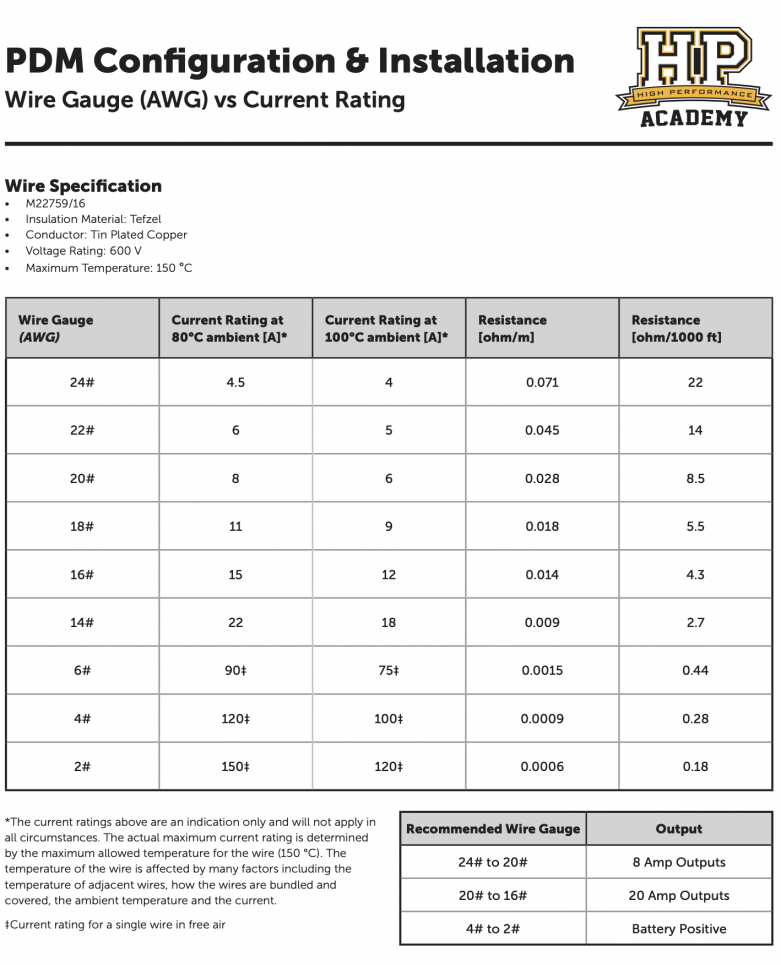

To help with wire sizing, we’ve included a worksheet (pictured above) showing different wire sizes in American Wire Gauge (AWG) and their current handling capacity. It also includes metric equivalents since Original Equipment Manufacturer (OEM) documentation, particularly for Japanese vehicles, often uses metric units.

This is all what we deem to be essential knowledge for anyone interested in automotive wiring, and as such it is covered in more detail within the lifetime access HPA Wiring Fundamentals Course.

Common Rules of Thumb for Wire Sizing

While it’s essential to calculate the current draw for each component, for modified street car wiring harnesses using TXL wire, here are some common rules of thumb:

- Ignition coils: 18 AWG wire for power and ground connections.

- Fuel injectors: 22 AWG wire.

- Sensors and switches: 22 AWG wire for power, ground, and signal.

- High current loads (e.g., fuel pumps, cooling fans): 14 AWG wire.

Although these values provide a good starting point, always double-check to ensure the wiring is adequately sized for your specific setup.

What About PDM Wiring?

When setting current limits for Power Management Unit (PMU) or Power Distribution Module (PDM) output channels, it's essential to size the wires to handle more current than we would for our traditional fused wiring applications. By setting the current limit above the expected operational current draw (covered in the PDM Installation & Configuration course) we ensure the current limiting will not interfere with the normal operation of the device.

For example, if you have a thermofan that draws 12 amps under normal operation, you might wire this to the PMU output channel using two 20 AWG M22759 wires in parallel. This configuration simplifies harness construction and connector selection. You would then set the PMU current limit at around 150% of the normal draw, or 18 amps in this case. This ensures the current limit won’t be triggered during normal operation but will trip in the event of a malfunction, such as a jammed fan or a wiring fault that shorts to ground.

If the fan experiences a sustained current draw just under 18 amps, the wires won’t get hot enough to be dangerous. However, if the current spikes above the limit due to a fault, the PMU will shut down the circuit before it can cause a fire.

A guideline for setting current limits is 150% of the device’s expected draw or the wire’s current rating—whichever is lower. However, other factors come into play, such as the wire’s proximity to external heat sources like a hot exhaust system. Heat reduces the current-handling capacity of wires, so in cases where the wire is operating near its limit and exposed to external heat, increasing the wire size may be necessary. This helps prevent overheating and allows the PMU current limit to be set safely above the operating current.

Conclusion

Correct wire sizing is crucial in any wiring harness power supply design. Undersizing wires can lead to dangerous overheating and potential fire hazards. Always calculate the current draw for each component and select the proper wire size to ensure safety and efficiency, as well as saving you time and money doing things twice.

If you want to learn more about wiring for automotive applications with an emphasis on motorsport wiring, enrol in the Wiring Fundamentals Course for a solid start down the right path.

Comments

If only one injector is being fired at any one time, then surely the wire before the splice can be same size as wires after the splice...

- peterguk United Kingdom

44 days ago

No one has commented on this page yet.