| 00:00 |

Most modern ECUs will provide the ability to compensate the fuel delivery for changes in intake air temperature and since this is quite critical, we will start here.

|

| 00:10 |

This compensation works on the principle that hot air is less dense and hence contains less oxygen.

|

| 00:17 |

As temperature increases, we therefore need less fuel to maintain a stable and consistent air fuel ratio.

|

| 00:25 |

Setting the IAT correction table in the ECU is pretty simple.

|

| 00:30 |

If you have taken our EFI Fundamentals course, you would have learnt how the density of air changes with regard to air temperature.

|

| 00:38 |

In simple terms, we find that as air temperature increases, air density drops by approximately 2.5% every 10 degrees.

|

| 00:47 |

Conversely as air temperature drops, the air density increases by 2.5%.

|

| 00:53 |

It shouldn’t be hard to draw the conclusion that our air temperature compensation table should make similar adjustments to the fuelling.

|

| 01:01 |

Since under standard conditions, air temperature is defined as 20 degrees centigrade, so we can fill the air temperature compensation table with 0 at this point.

|

| 01:11 |

Every 10 degrees hotter, we want to reduce the fuel delivery by 2.5%, and every 10 degrees colder, we want to increase fuel delivery by 2.5%.

|

| 01:22 |

If we fill in our air temp compensation table like this, we should see a consistent air fuel ratio, regardless of changing air temperature.

|

| 01:31 |

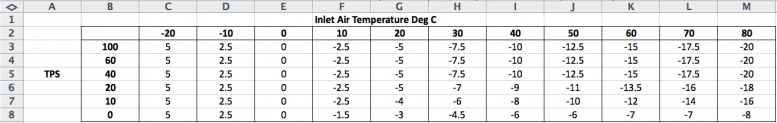

If your ECU has the ability to use a 3D table, you can benefit from adding a load axis using throttle position.

|

| 01:40 |

Often we see heat soak in the intake manifold adversely effect the reading of the intake air temp sensor, and this can have the sensor falsely reading hotter than the actual intake charge temperature.

|

| 01:52 |

This is common after you have run an engine, shut it down for a few minutes and then restart it for example.

|

| 02:00 |

Using a 3D table can help by allowing us to reduce the amount of trim the air temp compensation has at low throttle openings.

|

| 02:08 |

At large throttle openings, the increased air flow will quickly reduce the effect of heat soak and we can leave this area of the table untouched.

|

| 02:17 |

A sample 3D air temp correction table is attached as an example of how to set this up.

|

| 02:24 |

Lastly we have been talking about maintaining a stable AFR as temperature changes.

|

| 02:30 |

Particularly as the air temperature increases, the engine may become more susceptible to detonation and targeting a richer mixture may help safeguard this.

|

| 02:41 |

You can choose to use the air temp correction table to achieve this by increasing the compensation at higher temperature.

|

| 02:49 |

For example if we have tuned the engine to run at 0.80 lambda and we want to richen the mixture to 0.75 lambda above 40 degrees air temp, we can add the desired change into our air temperature correction table at 40 degrees and above.

|

| 03:06 |

Normally we would have a correction of minus 5% at 40 degrees as this is 20 degrees hotter than our standard operating temperature.

|

| 03:15 |

To move from 0.80 lambda to 0.75 lambda, we can calculate the extra fuel we need to add as a percentage by dividing the actual AFR by our desired AFR.

|

| 03:27 |

In this case 0.80 divided by 0.75 equals 1.07 or 7%.

|

| 03:35 |

This means we need to add 7% fuel to move from 0.80 to 0.75 lambda.

|

| 03:41 |

If we now add this 7% to the 40 degree cell of our air temp correction table, we would end up with a value of plus 2% which is the original minus 5% correction plus the trim of 7% we just worked out.

|

| 03:56 |

You can use this technique to achieve whatever safety parameter you wish in the fuel table as air temperature changes.

|