Sale ends todayGet 30% off any course (excluding packages)

Ends in --- --- ---

Keep everyone up to date with how your project is coming along.

Well this project of mine has taken so many back seats to other peoples cars over the years, its been well over a decade in the making now. But last year I took the decision to not take on any more work until my build was running and driving car. I've signed up a few HPA courses as I kind of like to it all my self, and HPA is being a great help in the wiring and Tuning departments. OK quick list of the build :-

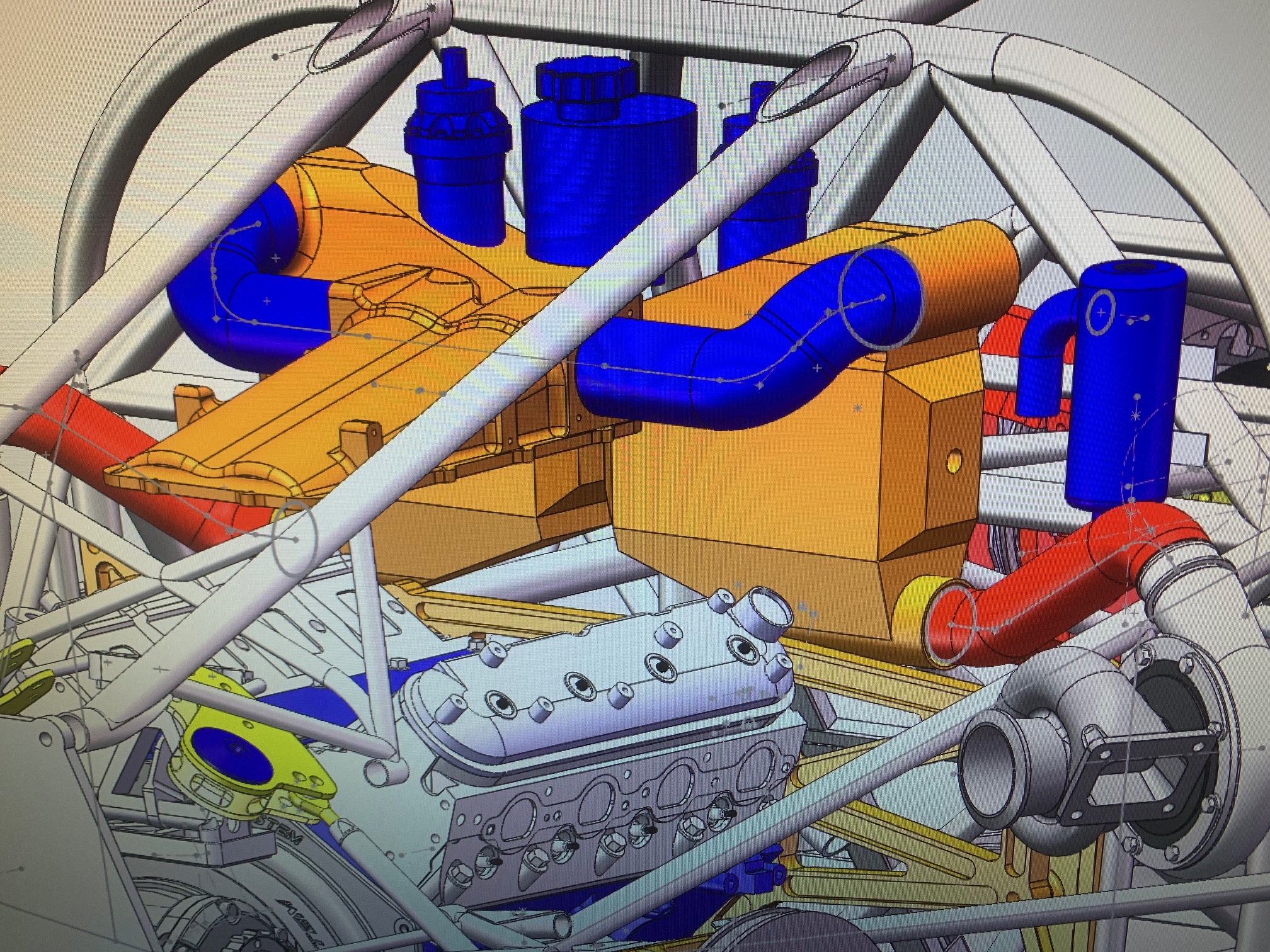

Full Tube frame Built in Solidworks with semi structural LS based engine.

All Billet work done in house on my old CNC mill.

996 Turbo Transaxle rebuilt by CMS with taller gearing LSD and oil spray bar

RHS Block 60mm Cam 4.125" Bore x 3.5" Stroke, Callies light weight Magnum XL crank, LSX GM 6 Bolt LS7 heads ported

SmallWood custom cam red line 8500 hopefully peak power about 76-7800 with twin Borg SXE64.5mm Turbos

Emtron KV8, HP8441 PDM, ( Dash not yet made my mind up but Probably AIM MXG1.2 )

My Most complex but multi use part was the motor front plate it allows me to mount the engine and all the belt driven ancillaries as low as possible... Fun once done but very wide and took multiple setups on the old mill to machine.

Complete back end unbolts to allow for engine removal

Rear was packaged tight as i could to make a 1.7M long working Diffuser that's starts under the fuel tank which is between the cockpit and the engine of course for best protection..

After a year of finalizing the body, I've started to make the body tooling ( as the Bucks are heavy and full of filler foam and wood to generate the shapes)...

Ive built a Body looms before but not a EFI engine loom so the first test of my HPA training is going to be the KV8 loom.... will update once ive started that....

This is next level. Well done so far!

I missed this before.

Very nice project and a lot of hard work, I'm impressed.

It looks like you may be using the cockpit bodywork from an existing series, smart move as windscreens can be one of the biggest issues for the home builder.

Wow, that is impressive for sure!

#subscribed

Well done what a great project, your wife must be hating it tho, keep up the great work

KV8 loom plug kits, Mounting kit, Wideband Sensors O2 and Knock, ID1050X injectors, HP8441 PDM and a 12 button CAN Keypad just a small list of the stuff arrived in the last month.... Still plugging away with the tooling has to be thick and slow to keep the accuracy so single layers at a a time slows things up some what..... But Side pod tooling almost there, rear diffuser finish tooling done and have started polishing it...... And on a training front realizing I needed to understand CANBus as I have a ECU, DASH, PDM, Keypad, TPMS and a steering wheel remote I/O board all needing to communicate so the HPA CAN course was another purchase of course !!

Just a little testing to cheer me up ....All good

Very impressive! Looking forward to seeing more progress. What events are you planning to compete in?

Only be competing with myself to be honest. Only plans are to try and set some good lap times at various tracks around North America, compare them to known road registered cars etc.... This is a rolling advertisement and Demo car for me. I'm presently taking molds of the body so I can build as many as I want. All ready have a customer wanting a S85 V10 version, which will only just fit in with a slightly smaller fuel tank and a fancy Xtrac transaxle which has the clutch at the very back. Also building 962 recreations for people first one was just a customer build with a 997 GT3 RS motor and a Elite TXL300 trans, but got so much attention I bought another body and have a customer wanting a 996 Turbo / Xtrac combo built next year... So will pull molds of that car before it goes to him..

[img ]https://www.hpacademy.com/forum/build-threads/editpost/

Watched all your videos on youtube. Really impressive.

You watched all my Videos on youtube... WOW that's a lot of spare time you must have had bud.... Thanks for watching.... more to come soon things are picking up on the build now.... Just pick up a Powertune Digital Dash and after much procrastination I'm finally making the Billet top cover to the Holley Hi Ram with twin entry's for the pair of 75mm Bosch Motorsport DBW throttles.....

Your living the dream, would love to be doing what your doing.

Thanks Brain, just had a life and reality check for 2 weeks had C19 hit me and the wife bad, thought I was a goner for a few days... So got a new lease on life and screw the money I need to finish my own car before i start another customer build.... Then maybe I can go full time at some point..

I had c19 a week and a half or so ago and still feeling the affects. Not flu symptoms but the lack of energy is wrecking me at the moment.

However must push on so I am learning the finer art of fibreglass at the moment with a custom dash build for my corolla. Really interested to follow this build of yours, shows some talent for sure. The amount of information you are sharing in your videos is also helping me solve other problems before they are problems so thanks.

Well if there helpful to you then I’m glad bud.. Good to share what I can then learn from our HPA friends what I don’t know YET 😉

Been busy making all the tooling for the body. God i didn't realize how long it would take.. But nearly there now, last big mold started now for the rear clip... Should have it all in the same white colour soon. Then I can finally start actually building the car and wiring the thing... Went for a PowerTune Digital dash in the end and cut a nice billet enclosure for it, the Shift lights and the warning lights... All Can bus switched of course.. And built a Carbon Wheel with printed hang Grips. Will get it professionally trimmed.

Been busy making all the tooling for the body. God i didn't realize how long it would take.. But nearly there now, last big mold started now for the rear clip... Should have it all in the same white colour soon. Then I can finally start actually building the car and wiring the thing... Went for a PowerTune Digital dash in the end and cut a nice billet enclosure for it, the Shift lights and the warning lights... All Can bus switched of course.. And built a Carbon Wheel with printed hang Grips. Will get it professionally trimmed.

New Front Clip and both side pods fresh out the molds nice and light, unlike the first prototypes I took the tooling off.

Turbo System took a few twists and turns developing but have gone for a Charge-cooled system in the end. I sacrificed putting the system up higher than i would have liked but was running out of room trying to keep the weight down...

Turbo System took a few twists and turns developing but have gone for a Charge-cooled system in the end. I sacrificed putting the system up higher than i would have liked but was running out of room trying to keep the weight down...