Sale ends todayGet 30% off any course (excluding packages)

Ends in --- --- ---

Commonrail diesel fuel injection systems. We often shout bigger is better on fuel delivery and there are loads of tuning shops able to give you just that I think and yes quantity of fuel is there but dos it make clean power? White to grey haze on low engine load where boost pressure is not so great and soot mass or better known as smoke well plenty.

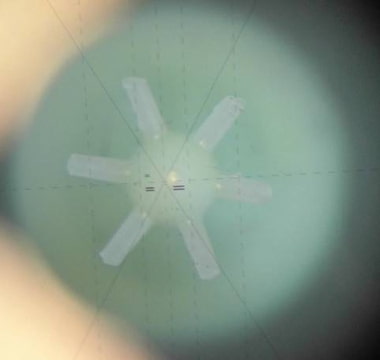

In our case diesel industries takes care of it own having for example our nozzle made by OEM supplier R&D department to get hi quality of fuel injection. Best and easy way to go forward to find the injector that is able to support the fuel delivery but often the nozzle is unable to do so as for chance that we blow the tip of the nozzle off as for having take to take out a lot of material to create a bigger nozzle hole size. Easy way is to just EDM the nozzle holes not taking out material to optimise fuel flow going into the nozzle holes but that means the quality of injection usually becomes very bad defeating the idea building a massive bigger injector that’s that still has excelled clean performance and stability. So in order to get this excelled clean performance loads of material from inside the nozzle needs to be taken out weakening the nozzle tip as a result so what to do? Build our self a new nozzle by eider offsetting the holes in two rows creating more space between the holes of go down in number of holes. It all depends. A other factor that is often overlooked is dos the diesel cone shape spray pattern coming out of the nozzle hit something like piston or cylinder head or even dos the cone shape overlay making a mess of things as well. Shape of combustion chamber dictates what the nozzle needs to look like as well.

And the last bit. Stability. Needle lift and shape of needle go hand in hand in good performance and often if you over flow the injectors injector close time expand like creasy giving the idea it’s a hi flow injector but in reality end of injection is way more retarded than you think. So also there a fine balance is needed. Good thing is most project I do have last generation fuel systems have the best what a OEM can deliver on tolerances and production techniques.

With a good engine set-up including fuel system hitting lambda 1 all the time is possible. That’s how we win races setting new standards even. More performance by efficiency.

Next up low lambda reading from a o2 sensor without having smoke. How is this possible?

During the process of making the nozzle measurements are taken to verify tolerances and so we are able even with massive more injector flow getting the tolerances of injector quantity offset within factory specifications of the standard injector.

Also read this http://www.diva-portal.org/smash/get/diva2:159595/FULLTEXT01.pdf