Sale ends todayGet 30% off any course (excluding packages)

Ends in --- --- ---

Let start with the basics of reading l Lambda. Most think we can do the job with a l Lambda sensor. In reality what some call a Lambda sensor is a o2 sensor that can only read the oxygen contend in a gas stream so dos oxygen content give you a correct l Lambda reading?

Exhaust gas on a diesel engine can be fragmented so very possible that hi oxygen content due to valve timing and combustion chamber scavenging gives a hi Lambda reading. Other example can be that air trapped near to the outer sides of the combustion chamber dos not take part in the combustion process. Theses things will mess up the real Lambda number of the combustion as well but will give a hi Lambda reading in general and mostly on older diesel engines even with a hi Lambda reading the engine will create soot mass better known as smoke.

We run some last generation diesel engines that can go as low as 0.88 Lambda reading still not producing soot mass or smoke so how can this be?

Fist of all these engines on valve change over have both inlet and exhaust valve closed so combustion chamber scavenging @ low RPM dos not take place so we have an X amount of trapped gas of the combustion that dos not exit the cylinder. On top of this there is an X amount of EMP (exhaust manifold pressure) present as well trapping some more combustion gas, or your can also call it EGR in the cylinder as well. This dos not sound very good as we now missing some oxygen content but there are good things to it as well. One of them is temperature in the piston dome helping to speed up the process going to a gaseous state with the diesel fuel. Also EGR contains inert gas slowing the combustion down a bit due to CO2 that dos expand a bit as well during temperature rise during combustion so we are getting some benefit as for a more controlled combustion and some gas expansion contributing to engine performance but this all dos not explain the 0.88 l Lambda number with no smoke making good power even having the same fuel per stroke ratio compared to engine with low RPM combustion chamber scavenging so there are more differences like low swirl in combustion chamber to avoid the fine spray of diesel injection mixing up so you get bigger diesel droplets that go to a gaseous state slower possible hitting the relative cold piston dome.

Even do more fuel injection pressure is used on modern diesel engines and there for more nozzle velocity the distance that the flame front takes place from the nozzle outlet is identical to older fuel systems with lower injection pressure but the distance between the nozzle holes is less as more nozzle holes are used on some injectors so the cone shape of the diesel spray are almost overlapping so hi swirl on gas flow inside the cylinder before ignition can real mess things up.

I strongly believe running your modern diesel engine around l Lambda 1 will get you the best results on performance so the 0.88 l Lambda along with some EGR gas dos not line up with that picture but it is reality on what the oxygen sensor(s) are reading including the one from the FIA organisation on FIA European truck racing. Also both o2 sensor are placed opposite to eats other and the readings have sometimes differences as well so can we conclude due to the large fragmentation of exhaust gas content a normal o2 sensor can not read real l Lambda or are we making more engine performance with lower l Lambda numbers when some conditions are met?

During the meeting with the FIA organisation regarding l Lambda I was asked when do you smoke and @ what l Lambda number? As we run on HVO100 or EN15940 diesel fuel still using the fuel model for normal EN590 diesel. My answer I do not know what l Lambda number we can run getting smoke and all I know running this engine close to l Lambda number 1 I lose 12% performance.

Some conclusion based on ECU data. Must say on this engine type did not use l Lambda number as a reference as we get no good reference just looking a engine performance in relation to fuel model not even looking @ EGT even.

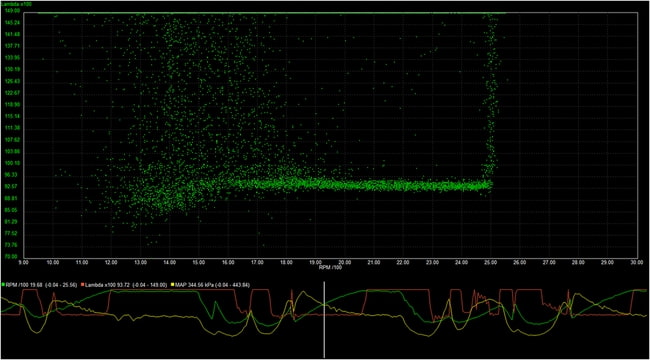

In this picture you see l Lambda numbers scatter plot running on original fuel model. As you can see more solid line on scatter plot. NOTE! l Lambda numbers are times 100 so 100 is l Lambda 1 and a 88 is l Lambda 0.88. get it!

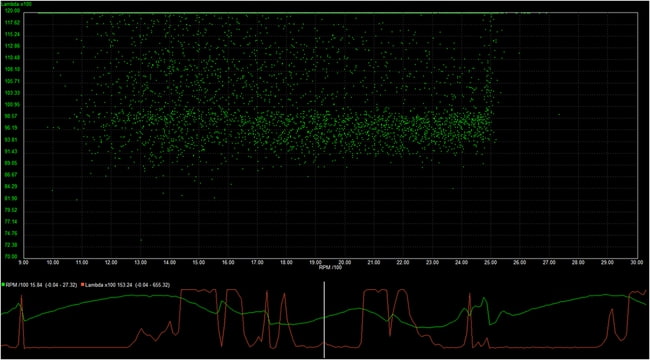

Now here is a scatter plot with l Lambda 1 target. As you can see all dots are all over the place indication there are random points with low l Lambda numbers.

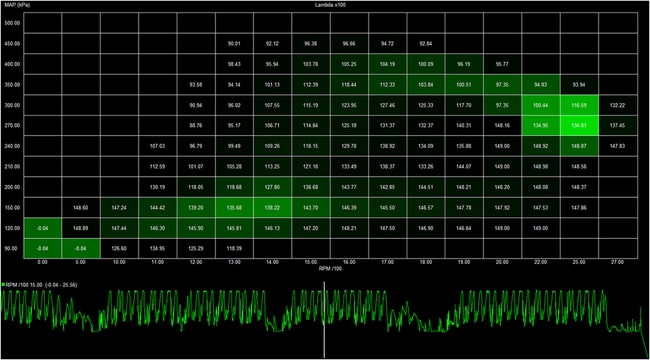

Now looking @ the histogram running original fuel model this is what you get. l Lambda numbers very close to 1.

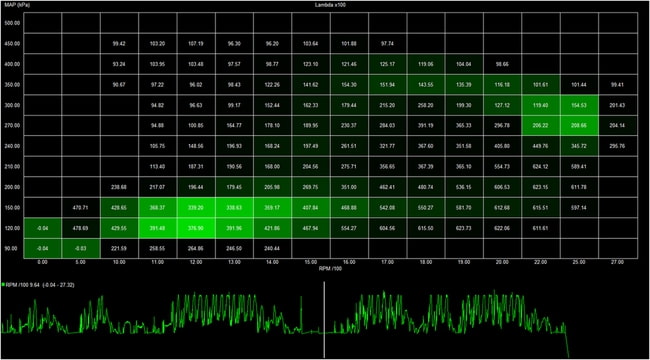

And this is the histogram running Lambda 1 target. Only a small difference there on Lambda reading but less engine performance.

I know this is getting real technical also indicating a diesel engine is more complex than most think and its not reading a book on how to but read between the lines and use read data to make progress.

3e generation Scania 13L XPI exhaust camera trace truck engine running on hungaroring ETRC

Credit to Scania able to run this hi performance engine with more than 95% original standard parts running very lo soot mass or smoke and possible NOX reduction on HV100 bi fuel. Definite the way to go forward for truck racing strongly believer performance and emission reduction can go hand in hand on motor sport application however it will take time before race organisation will embrace this latest development and new standard must be set in order to improve. We hope to take the lead in this developing other engines brands to the same standard as the 3e generation Scania 13L XPI engine.

[url=https://www.youtube.com/watch?v=vnX0FviYvgI]https://www.youtube.com/watch?v=vnX0FviYvgI

If I am correct you are Baldur!!!.

I'm tired of the general misinformation and little understanding of how diesel engines work, even more serious in common rail systems.

I have read a ton of information from books, scientific articles, forums and have asked "experts" on the subject and I am surprised by the confusion that exists regards the combustion of a diesel engine. After experimenting with your DID1 ECU, I felt completely ignorant when I realized that many things I "thought" I knew were wrong. Today after having read all your posts in this forum I can only say. Infinite thanks for your knowledge. What a pity that it is not valued here (or understood hehe)

Please, it would be a delight for me as well as for diesel lovers if you continue sharing your knowledge.

Greetings all the way from Ecuador.

Lets have more of this. I like the discussion.

C