Sale ends todayGet 30% off any course (excluding packages)

Ends in --- --- ---

Yesterday I have done a Mercedes G class with OM606 engine tuned with VNT turbo a big Dieselmeken EDC fuel pump controlled by a Baldur DSL1 ECU.

Mercedes OM606 is a legend among small diesel engines able to make easy over 500Hp power on stock engine and yes bigger fuelpump in combination with S200 or S300SX-E turbo still able to use it as a daily drive with a lot of oumpff if needed. LOL.

Did take my time and fine-tune the start and idle fuel so that the engine runs just as smoothly with the larger fuel pump as if it were a standard engine.

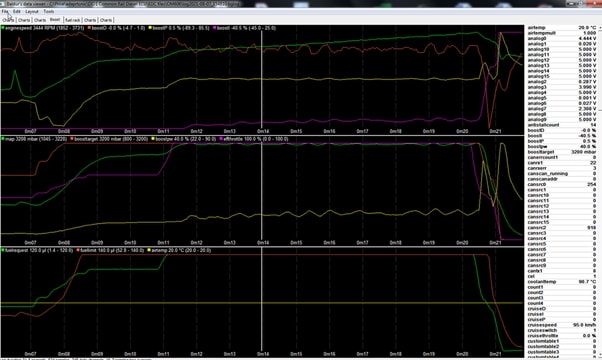

What I wasn't too happy with is the VNT turbo that my client got pressed into his hands. This one does what you need, we put a bigger compressor wheel in it, now it easily makes 2.5Bar turbo pressure and 350HP. If our turbo experts only opened their eyes then you know that the compressor wheels have improved in recent years with air mass displacement etc but have not gotten bigger in recent years. Another thing is that most VNT turbo designs are quite recent, so go ahead and improve on that! OK but what is the effect of putting a bigger compressor wheel on an existing VNT turbo??? Very simply the turbine has to deliver more torque to be able to turn the larger compressor wheel and for that you need more exhaust pressure to generate torque and with a VNT turbo this is also possible because there are adjustable vanes in the exhaust housing of the turbo that allow you to so the exhaust gas flow can squeeze causing it to blow harder on the blades of the turbine. The VNT mechanism is controlled via an electronic activator by the DSL1 ECU and you have quite a few options in this ECU to get turbo and exhaust pressure under control. Run make data log and view and adjust parameters in the DSL1 etc.

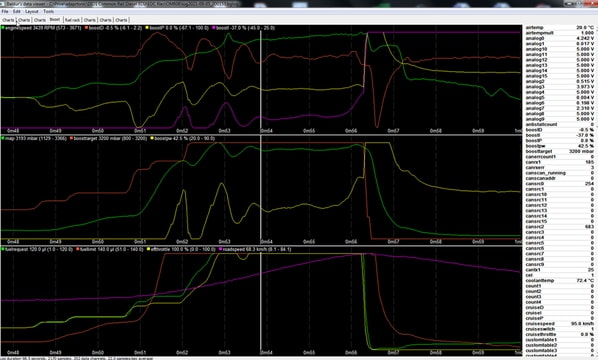

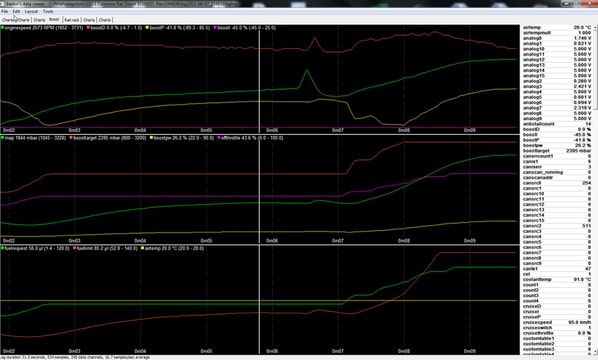

The OM606 is a hi revving engine, which means that they are quite sensitive to exhaust pressure. Too little turbo pressure and you have smoke, too much turbo pressure and with this pimped turbo also too high exhaust pressure and you also have smoke because the engine simply does not want to breathe. The advantage with an electronic activator for the VNT system is that you can see in which position it is, see picture (boostpw) where it is roughly open at 41%, 10% is fully closed and 90% is fully open to get an idea . The normal picture with a VNT turbo is more boost, more fuel and then you see that the activator opens the VNT vanes more because more fuel also gives more exhaust gas volume and therefore the balance between turbo and exhaust gas pressure remains fairly equal with only a peak in the exhaust gas pressure while spooling up the turbo that you close the VNT vanes for a little extra if you know how to hit the accelerator pedal well and therefore the turbo pressure flies up.

VNT turbo, they perform well are compact but little more complicated than conventional turbo so often some more control is needed to get the max out of your set-up so we mainly use a good aftermarket ECU systems to handle this and if possible a electronic activator as for good VNT position feedback and compact easy install.

very informative thank you this is something i have had no experience in, so it is great to see an example like this

Regards Ross

Thanks. Nice post.

I have read about some nice OM606 builds with mechanical pumps that give good power.

How did it works with EDC pump. Is it an electronic actuator instead of the mechanical connection between accelerator pedal and the dieael pump, with mechanical governor? Or is it only electric actuator on the rack, and the governor function in the computer?

On this car there was a Baldur DLS1 ECU controlling the standard EDC activator that controls the fuel rack on the fuel pump as well as the HELLA electronic activator on the turbo. Loads of options here to get it all working but some know how is needed to set up these EDC systems. Think most OM606 work in combination with a AT and these engine can make good power making torque reduction during shifting essential and having good CAN communication with the TCM (aftermarket or stock) will make your ride a lot better as well. This ECU box can do it all including traction and stability control that came as standard on the cars running the OM606 engines.

Must say I was impressed after spending some time setting things up like start and idle fuel making it run like it was a stock fuelpump but the fuelpump on this project is well in the range of making 450 to 500Hp so fuel rack travel stability is a must to get smooth running.

Back begin 90 ties these EDC governor systems became popular as your get more control on things and we had to set these up getting to know all the tricks to get them working along the way.

https://www.aftermarketecushop.com/diesel-ecu-ecm/dsl1-ecu-for-diesel-ecd-fuelpump

Next step in this VNT turbo soap series. Company that did deliver the stock well almost stock turbo did something better. NOT! They chance the VNT vane position to the electronic activator and as this OM606 dos not like hi EMP or exhaust pressure as it will open de exhaust valves and as this engine has hydraulic lifters on the valves they stay open for some seconds before the valve clearance is back to normal. If this happens your engine will sound very unpleasant and if you did not know any better you could think this was the end of my engine. Well stay calm turn of your engine so oil pressure drops and start it after some seconds an all will be fine and back to normal.

So now the vanes are closing to far so I not only have to re calibrate the activator to vane position also the PID loop needs different settings as this turbo spools a lot faster so looking @ the boost or effort to the activator needs to be less a aggressive so lower gain setting there needed.

Also interesting to see the effect of the NVT vanes closing to far even reducing even boost. A event that happens between 0m52 and 0m63 on the time line stamp, have a look @ map in relation to boostpw. So all in all VNT turbo not always easy to make a perfect set-up and some are harder to dial in than others. Personally I think something like a S200SX-E works better on these OM606 engines.