Sale ends todayGet 30% off any course (excluding packages)

Ends in --- --- ---

I am after some documentation regarding the system 25 standards, I noticed Ryan posted about how he email someone and had this sent to him.

So far i have found this PDF which has some good reading but leaves out a lot and doesn't cover any twisting, boots or lacing techniques.

I'm trying to work out if my concentric twisting is correct.

What angle do you guys tend to lay up each layer at? I originally tried a really shallow angle (about 10-15 deg) and it didn't really work out to well so i am now working to about 25-35deg of angle. Does this seem about right?

Should my angle increase as the layers stack up?

Any help would be much appreciated.

I twist around 37 degree or so give or take a degree through all the layers. I believe trigonometry can show that the angle will remain the same no matter the growth of the layer (visually it may look like it's getting tighter, and it's tougher to tell because the harness is round and not a triangle lol). That comes with practice as to what "looks" right as well

I've attached a couple of "motorsport" system-25 docs. The catalog has many many docs on how to wire this and where to ground this, shrink this and that etc. but the ones attached cover 80% of what youll encounter in the motorsport wiring assembly world. Don't say I didnt do anything for ya :)

Edit: Forgot to mention these were given to me by a representative of TE, these do not belong to me but they are publicly available, just a little hard to find :) the "256 COP" refers directly to the concentric twisting of wires. The rest are for every other curious soul

Thanks for that Ryan, Much appreciated mate.

I was just getting out the protractor and overlaying it on a few of smithracewires and your instagram photos. Hence the broad range of angles lol.

One last question for now. The kevlar lacing cord. Where do you source this from and what is the exact name of it, is it just kevlar lacing cord. It is the only product i couldnt find available anywhere. I have been able to source tefzel wire, kapton tape, dr25 shrink, moulded boots, rt-125 epoxy but the lacing cord seems to be the hard one.

lol no worries at all! Im here to help

Good question, I struggled finding this as well when I first started. But in my professional opinion, it's better to buy the kevlar from a reseller than trying to buy it from a manufacturer. The part number your looking for is KEVLAR-380 or ARAMID 380. Probably searching with the term "aramid 380 denier" might pull up some results. Kevlar is a trademarked name I believe. The 380 just stands for the denier of the thread

However, if you can find a company that sells it, they probably wont sell in small quantities, you have to buy 6000ft (1800m) minimum or something in that area (at least through the people I go through) I can't remember the cost, but I think it was in $300 range for it. If you need smaller qunatities (the kevlar lasts a while, trust me) I would order through Joel @ racespec, he stocks a crap ton of it and can cut to length.

Also, noticed your in Australia, why not give Motec a call and see if their wiring department will sell you some cord?

For the aramide (Kevlar / Nomex) lacing, that's the MIL-T-43435 Type V (-55°C to 260°C)

but you could also use a polyester (dacron) lacing, MIL-T-43435 Type II ( -73°C to +232°C)

The DR-25 is only rated to +150°C anyway

Prowire sell the kevlar lacing per foot if that can help:

Oh wow, did not know Prowire sold the aramid. Thanks for the info!

Thanks again Fellas.

Thats the funny thing about Australian companies that also have stockists overseas. It is generally cheaper for us to buy the product from the US dealer and have it shipped back to Australia, hence why i never even bothered to call Motec in Australia. Somehow shipping something across the globe twice ends up cheaper than shipping it across the city lol.

Im actually waiting on some stuff from prowire on backorder so i will get them to add some lacing cord too. I didnt know they had it either, cant believe i've never stumbled across it on their site.

Cambo, I have been grabbing stuff from Cambridge at a pretty good rate, shipping in 2-3 days. Fair bit cheaper than sourcing from Motec also.

Thanks BENchmark. Would be great if the minimum order quantity wasn't 30.5 meters. Do they sell smaller quantities to you?

Milspecwiring.com and prowireusa.com have 10ft(3m) minimum.

I'll ask tomorrow.

The last roll of 12ga we had delivered only had 10m on it, I know that.

I've made my concentric twisting first attempt yesterday. The core is shielded wire, the first layer is made of 6 wire but there is a huge gap you guys will be able to check in one of the pictures attached. The second layer I made with 12 wires just like I ready it should be done in some places. I liked the results very much, the flexibility, harnesses size and the aesthetic is awesome. I have a lot to learn and I hope to reach the level of you guys some day.

Looks really good Haruki. Once you make the switch to m22759 wire, you will notice even better flexibility, sturdier feel, and overall nicer look. The m22759 wire can also hold it's shape better after twisted :) Keep it up!

I'm coming across some doubts in a new loom.

It's know that the concentric twisting is based on:

Core

First layer: 6 wires

Second layer: 12 wires

And so on...

I've noticed that when using a shielded 3 22 awg as core, the first layer with 6 wires never looks good.

It always gets this huge gap.

I've started looking for some milspec wiring photos over the web and come across this one:

I've noticed that the core is a 3 wire shielded (as I'm intending to use) but there is 9 wires on the first layer.

The second layer 16 wires...

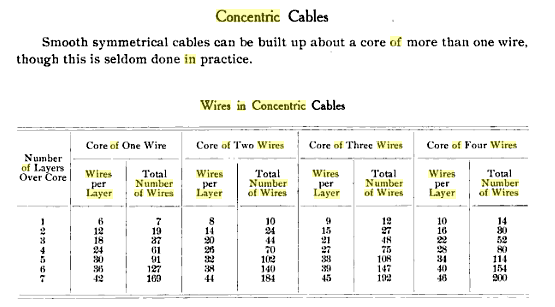

The system 25 says as follows:

I though that one 3 wire shielded cable was considered as 1 core wire, but is actually considered as a 3 core wire?

Based on that, the work from the above picture should have 15 wires on the second layer instead of 16, is that correct?

What I noticed is that this isn't an exactly science and some "rules" can be "adapted" in order to accomplish a concentric twisting without gaps between the wires, I'm right?

I have a few questions that have been brewing for years. This practice of wrapping wiring looms in heat shrink with shrink boots at the connectors is prevalent in motorsport. And it obviously has its roots in the military world, being mil-spec derived. But where? I've worked in aerospace, and the wiring on airplanes and satellites is not wrapped in heat shrink. It is left bare. It is not concentrically twisted either.

My suspicion is that heat shrinking harnesses may apply to ground based military equipment that is frequently manipulated by human operators. Say for radio equipment on Humvees, or for quick deploy satellite dishes. Things like that. This is just a hunch, I have no evidence to back it up. Does anyone here know more about that? If so it would draw a logical analogy with a race car. The need for high reliability in a harsh environment with frequency manipulation by human operators.

I also wonder about concentric twisting. What need does this satisfy? I've never done it because frankly I had no idea anyone did it this way until I joined this forum. I am assuming it makes a loom more flexible and reduces strain on the wiring during repeated manipulation (bending back and forth)? Or is it for EFI concerns? Or to make it easier to push the wiring through the heat shrink? Or to keep the loom more compact?

One thing this twisting would do I believe is make the loom somewhat heavier. Probably about 20% I guess. Wouldn't matter for most folks but in something like F1 I'm surprised they'd accept something like that instead of just tossing a harness every time it get's touched. Well, you get the idea. I don't know if F1 cars use one big harness of a series of smaller sub-harnesses with intermediate connectors. It's all a trade-off I guess.

@haruki.tutia the standards of increasing your wire count by 6 wires per layer assumes that you're using the same gauge wire throughout the harness which is not particularly common in reality. When you're using a 3 core shielded cable as the first layer then this inevitably is much larger in diameter than say a single 20 AWG wire core. For this reason you will need to manipulate the number of wires in the second layer in order to achieve the correct angle to the wires in the layer. Some of this does come down to a little experience with what looks/feels right.

@Dr G I think it's a little hard to compare the requirements for aircraft wiring to what we need in an automotive application. For the most part flexibility (which is one of the key advantages of concentric twisting) is not that relevant in an aircraft where a wire run may be 50 metres long for example. Likewise constant installation and removal isn't probably as common, and the DR25 heat shrink provides a fluid, chemical and abrasion resistant layer that again isn't too relevant to air craft use.

The main advantages of concentric twisting are:

1. Offers a high degree of flexibility in the finished harness

2. Ensures that stresses in the harness are evenly shared among all the wires

3. Achieves a small overall bundle size

4. Offers strain relief to any crimped connectors

As an aside though, if you're intending to use a heat shrink cover such as DR25 then it's incredibly difficult to do a tidy job of installing the harness into the heat shrink if you don't concentrically twist the harness.

Yes, due to the angle the harness is twisted at and the fact that you're normally going to add filler wire (wire that isn't actually doing anything other than achieving the required conductor count for a particular layer), it's inevitable that the harness will end up heavier than one where the conductors aren't twisted. F1 is a special case where they are using very small gauge wire as well as a special type of DR25 that's thinner and lighter than what we normally would use, that the weight increase is less significant and it would seem can be deemed an acceptable compromise for the listed advantages.

That being said my understanding is that F1 has taken things a step further and the new trend is to lay the majority of the harness into the carbon monocoque during construction. I'm not sure if this is a current technology on the cars we see now or if it's on the horizon.

Thanks for the advice Simon.

After a lot of time and going nuts about the number of wires on the first layer, I've achieved this result. It's far from being perfect but it's my first milspec ECU loom (my first was a pretty simple design for the rear tailights).