Sale ends todayGet 30% off any course (excluding packages)

Ends in --- --- ---

Hey Guys.

Here's some background. I've been using a Motec M800 for over 10 years and back then, it was the best that was available and Flex Fuel wasn't really a thing. Over the years I have added to the ECU at a considerable cost and I currently have:

Supra/2JZ Non VVTi.

Motec M800 with Advanced Functions / TC

Motec Dash CDL with 8mb and i2 Pro

Motec CDI-8 running 2JZ Coil packs

Titan Motorsports PNP Adaptor for the 2JZ

Motec PLM with LSU 4.9 Sensor

Considering - Motec SKM

Yep, I'm heavily invested in the motec hundred series ecosystem. The latest Link G4 Thunder is a pretty great ECU and that could be my stop gap before going to a Motec M150

Here's the rub, I want to go flex fuel with compensations and a proper flex fuel map that is compensated on the fly, much like the PS2000 / Elite 2500 does.

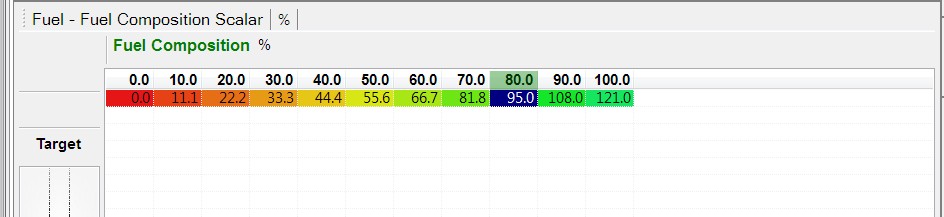

Attached is the Fuel Comp. Correction table and the Fuel Scalar.

AFAIK, the 33% trim is applied according to the % of ethanol content as detected in the scalar.

So at 0 Ethanol, 0*33% = 0. at E90, 1.08*33% = 35.64% correction to the fuel table.

It's possible to do away with the fuel composition map and just make a scalar map for the Motec as the trim value will the the same. 3D with %ethanol vs kPa

For IGN kPa vs %ethanol should work just the same.

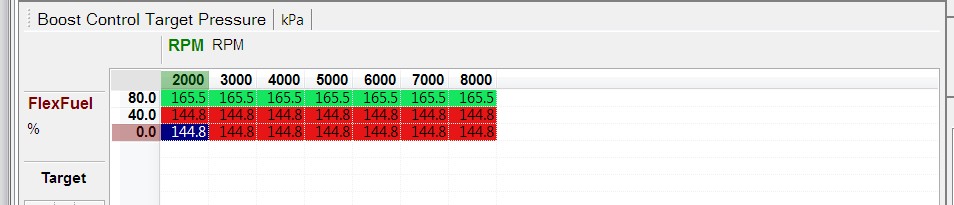

Boost - %ethanol vs RPM with % trim being the change factor. or %ethanol vs RPM for boost aim.

Every one that I've spoken to says that it can be done, however the Motec cannot accept the frequency input for ethanol content - it doesn't work.

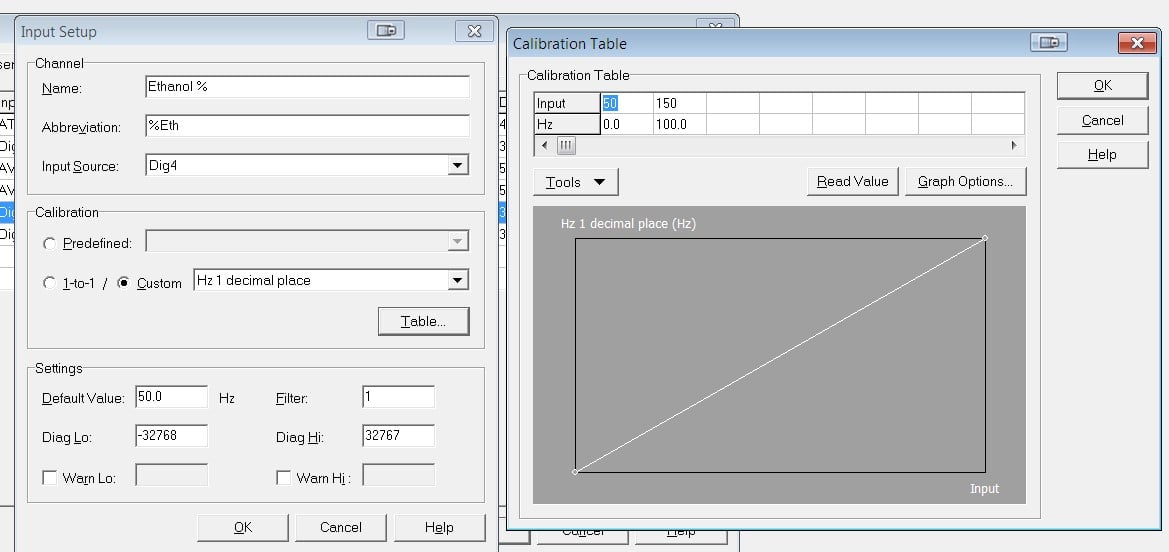

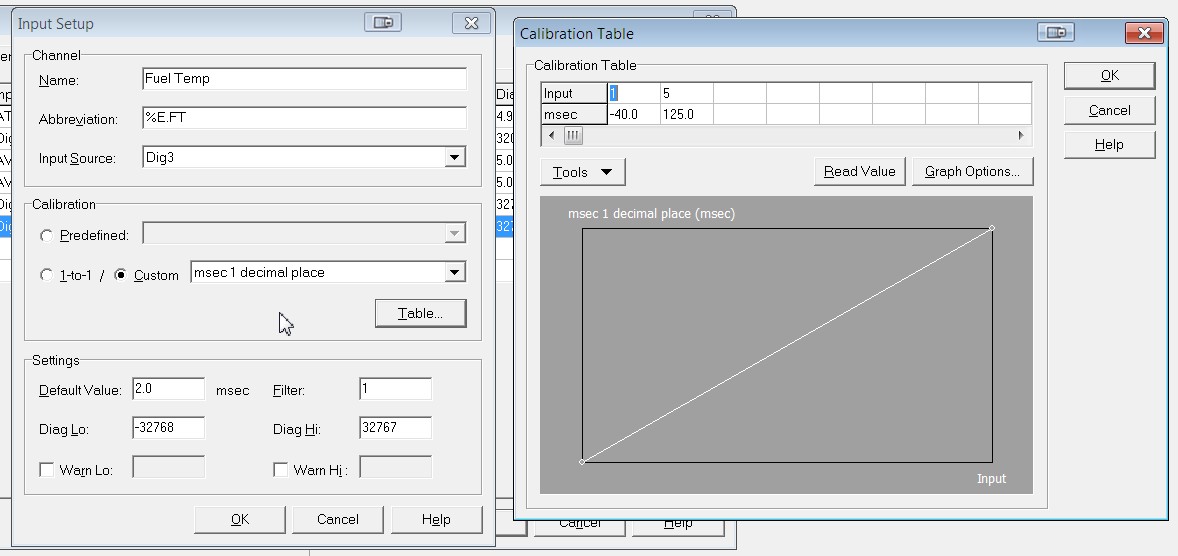

Flex Fuel Sensor info:

"The frequency of the signal indicates the ethanol percentage. The output frequency is linear with respect to the percentage of ethanol content in the fuel. The PCM provides an internal pull-up to five volts on the signal circuit, and the fuel sensor pulls the 5 volts to ground in pulses. The normal range of operating frequency is between 50 and 150 Hertz:

50 Hertz indicates 0% ethanol 150 Hertz indicates 100% ethanol. (interpolate in between).The pulse width indicates the fuel temperature. The normal pulse width is between 1 and 5 milliseconds: 1 millisecond indicates -40°C (-40°F), and 5 milliseconds indicates 125°C (257°F)."

Andre has mentioned that there is a hack/workaround to get it done. How is this possible?

I understand that Boost, Fuel, IGN etc can be compensated with Comp 1 3D table and Comp 2 2D table.

I've attached a map for a 2JZ Running Race E98 38-40psi at 100% injector duty cycle at full noise using Bosch 821 2200cc injectors. Approx 630rwkw on a chassis dyno.

So unless I've overlooked something - what's the secret to getting the Continental / GM Flex Fuel Sensor to work on the Motec M800 and apply these compensations in the Comp 1/2 tables?

If I'm wrong in my assumptions, please correct me and state what is right.

I don't want to have to give up on the Motec or really have to pay for an M150 right now to retain my ECU and Dash etc at full functionality.

Please explain why you think the sensor doesn't work? Here's how I believe you would connect & configure that sensor:

If you connect your flex fuel sensor to one of the digital inputs, you can use that with one of the User Channels (you can rename it, "Ethanol Content"). Set the Calibration to #77 Frequency (Hz) 5000 = 500.0Hz linear. That should make the output be 500 to 1500 depending upon the Ethanol Content. We could probably make a custom calibration table so this would read 0-100% directly -- I would hook up the sensor first and get some values.

If you want to get the temperature as well, then I would also connect the signal to another digital input, use another User Channel, and the calibration #80 Time(uSec) 5000=5000uSec linear. This would mean 1000 uSec (1ms) = -40degC and 5000uSec (5ms) would be 125degC.

Be sure the diags are set appropriately for each channel.

Hopefully that will work for you.

Hi David, thanks for replying.

Last time I was looking at this and speaking to a fellow tuner with experience with the hundred series ecu and the flex fuel sensor - he said that he could not get it to work reliably and it was a bug in the M800 firmware or hardware that was preventing it from being reliable. Ended up giving up and used a Haltech instead.

I've set it up on a Haltech PS2000 and Elite 2500 with plug and play results. "

Is the issue the non-native support and custom comp tables for the E85 sensor or is there a bug that doesn't read the 50-150hz output of the sensor for %Ethanol content?

I have setup the calibration on a dummy file and it's easy enough to do as a custom input based on the sensor data. Is this accurate?

If there is no sensor input issue with the M800, then I'll start on the E85 conversion and tune it on 98 first for a baseline and then tune it on E85 and calibrate the comp tables with the real data for an optimised map.

You need to test the sensor with the M800 to see what the input values for the calibration table would be. I think you need to pick the Predefined calibration first, then change to the Custom table. I believe then the input will be the output from the predefined calibration (since digital inputs need to know if you are measuring the pulse width or the frequency). If you can't hook up the sensor, then I would try simulating that (perhaps using an Aux Output looped back to the digital input).

I remember an old video of I think John Reed demonstrating flex fuel on an M800, where the car was running on the dyno with the tank practically empty and he poured E85 in and you saw the ethanol content increase and the lambda value stay steady. I found the video I was thinking of:

Thanks David,

I'll tune the car on Gasoline first then drain and retune on ethanol E85 and base my compensation map based on real world figures instead of a generic scalar.

Fueling is pretty easy it's more so having the timing optimised as well as the improvement on boost response.