Sale ends todayGet 30% off any course (excluding packages)

Ends in --- --- ---

Talk about engine building here. New products, tricky questions or showcase your work - If it's engine building related it's welcome here.

Hi

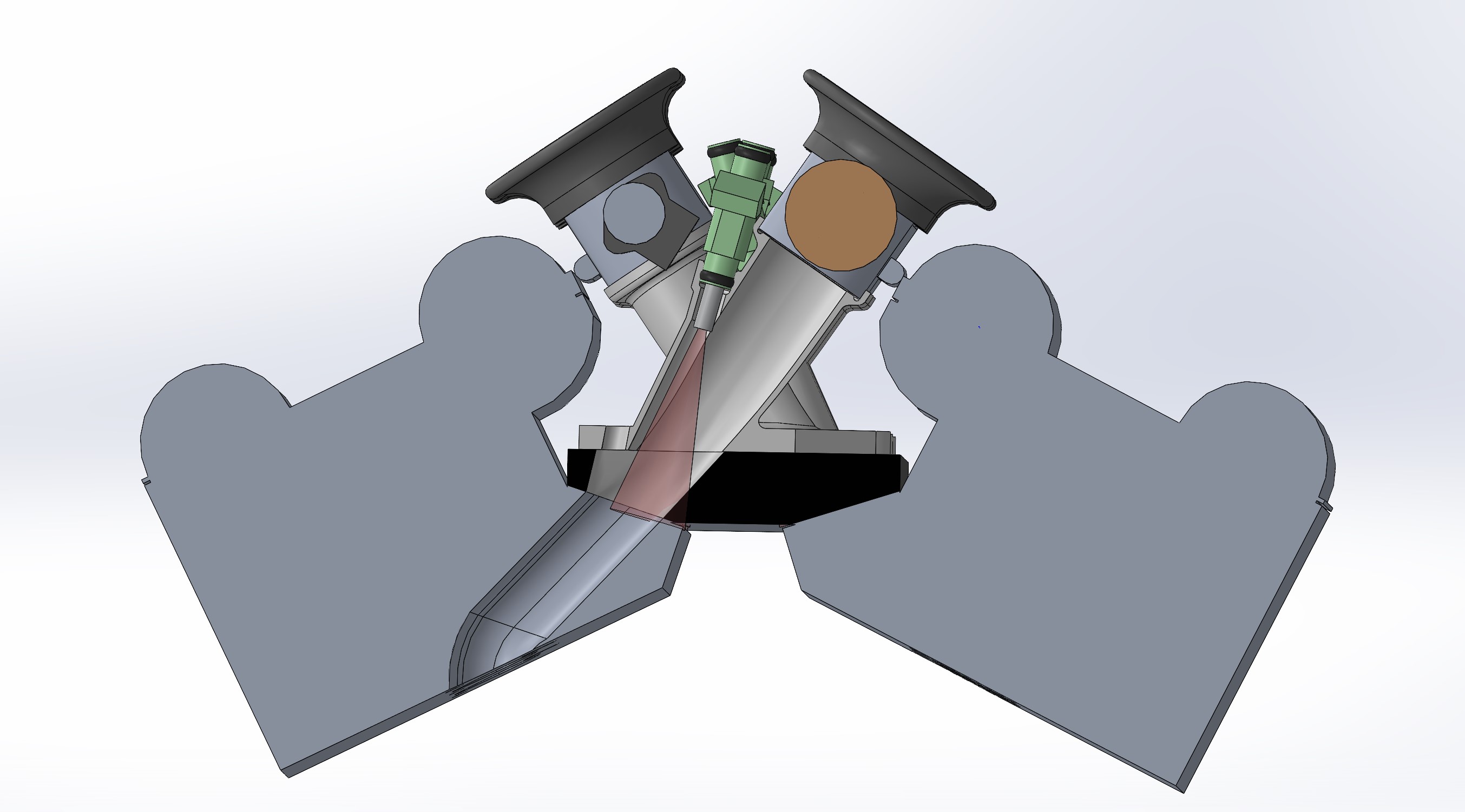

Trying design 3d printable intake manifold for ITB.

Plan print from A) Nylon carbon (local guy can print) B) Aluminum (china) C) 316L (china) - want print from Aluminum, but china quality not so good.

Black section is OE from "plastic", so heat will be lovered for part.

Dont have alot of space between heads so throttles will be up.

Hard to put injectors in orginal location (problem rail desing), so moving up.

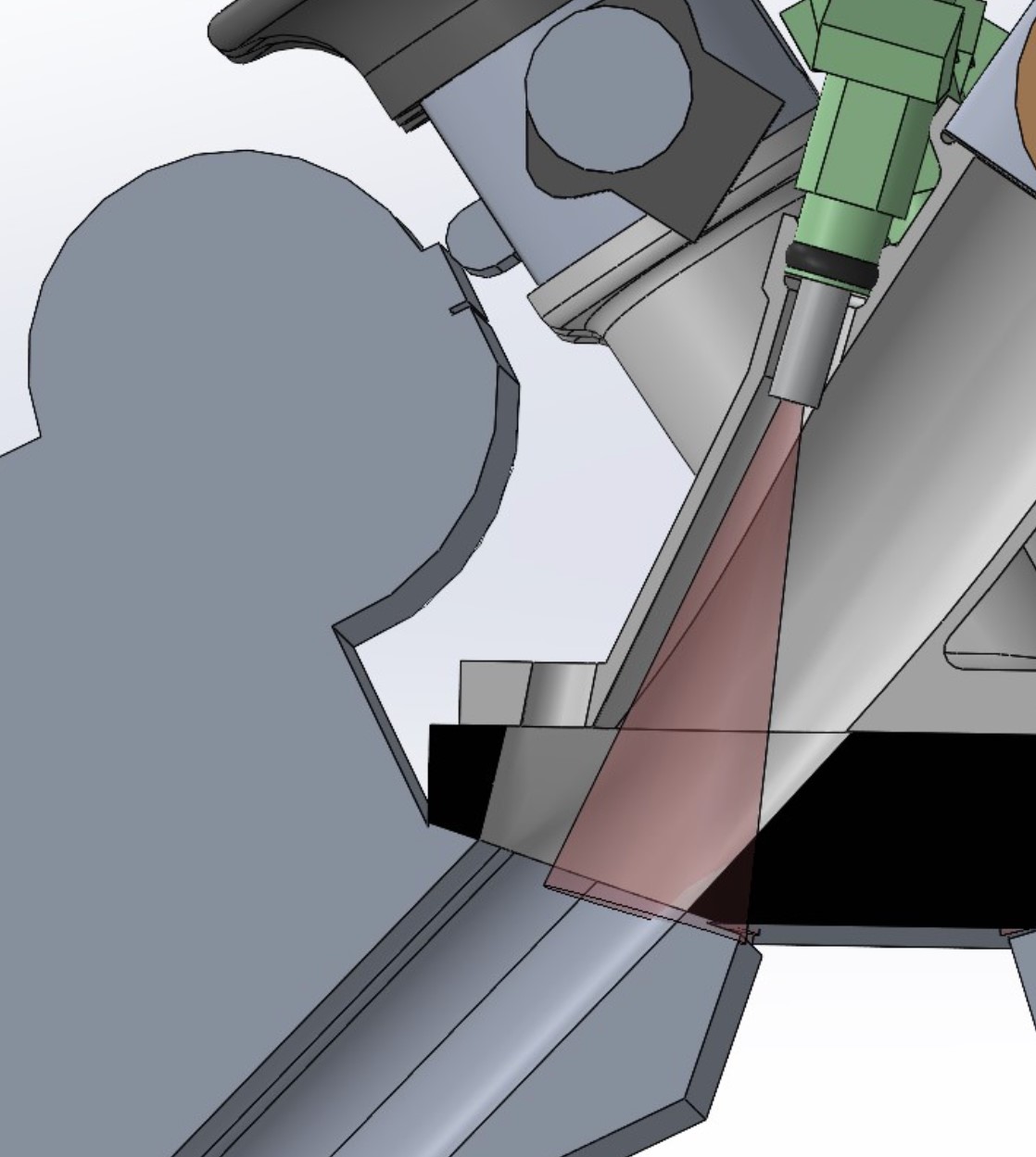

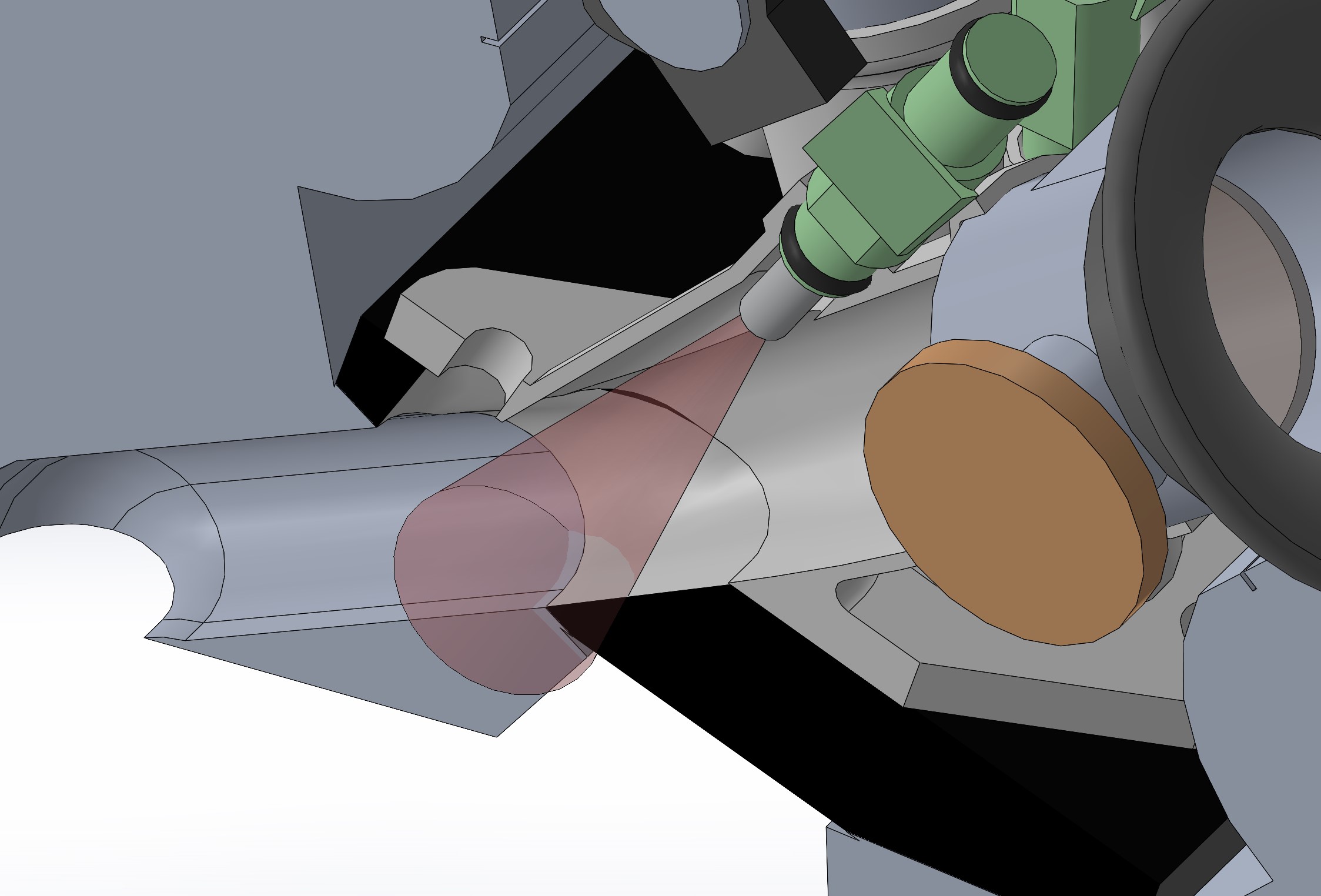

Trying find reasonable injectors intercept angle (to spray as directly as possible into the port), but still i think fuel will go on walls.

Injectors 0 280 158 124. Alfa 20, Gama 0, Delta 90. 381cc/min - "dual spray" - that i dont like, but nozzle dont look like dual spray. Trying find 10-20 Alfa angle, 0-15 Gama angle injectors.

Questions:

How much fuel film can I expect (possible alot going on "cold" plastic walls) ?

What other problems might I encounter?

Maybe someone tried 3d printed intake manifold?

p.s. now the draft is done for aluminum

After you've tuned for a while, you will understand that normally injectors are not spraying when the intake valve is open and the air is flowing at maximum velocity. Therefore, I would make the injector spray angle secondary to the ease of having a single fuel rail, or other packaging considerations. I would recommends looking for the best atomizing injectors, and perhaps run a higher fuel pressure to improve the atomization.

Fuel film can be tuned and how much goes on the wall depends on the manifold pressure as much as the injector spray angle. Remember the fuel should be atomized not a set of streams like a shower head. I would imagine the only way to have less fuel film by design to have a smaller manifold surface area.

That does look rather cramped, what sort of room do you have above the trumpet opening, and what sort of filter/airbox might you be using?

I was thinking it may be an option to have the injectors mounted to spray directly down the throats, normally this would be for top end and less efficient at low rpm, but needs must, and if it's a higher reving engine...

I dont have much expierence with ecu tune, but know fuel film can tuned, but if I can improve it by manifold design, I don't want to miss this opportunity.

Yes, I am looking injectors with good atomiziation, these are EV14 type injector - looks like newest generation, hope it will be good atomization (droplet size 50-130µm)

I'm a little afraid that due the low temperature of the manifold walls, it may have fuel condense on walls due this injector locations (as like cold engine do).

Space above - already have hole in hood for manifold, but dont want go higher than now.

Theoretically I can move injectors over throttles, but as far as I find, it will create a problems for me - driveability on low load, idle, air filter construction, but it will look cool :D

Air filter design still being considered A) individual 6x air filter B) 2x big air filter

I also don't know how ITB will react to air flow passing through them (when they stick out over hood), so maybe on big air filter is better

This diy car is more track toy, now reving to 7.5K, maybe in future 8K - not full race car, so want have street driveability