Sale ends todayGet 30% off any course (excluding packages)

Ends in --- --- ---

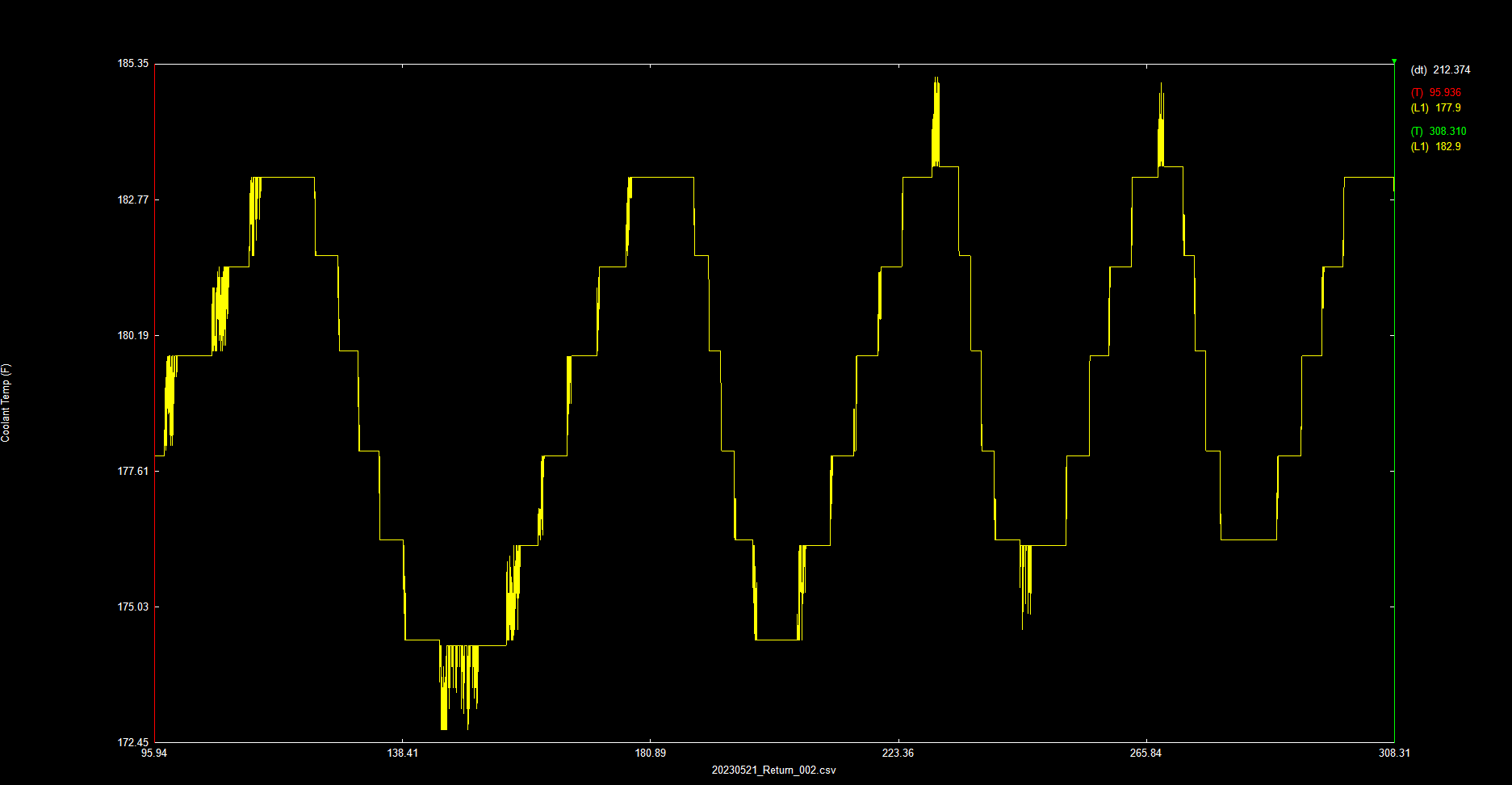

I am chasing a glitch in my system and not sure if it is electronic or mechanical. I noticed a large variation in my log files of the coolant sensor. A little background, the system is a Performance Electronics PE-8400. The coolant sensor is a GM 15326386, the typical 3/8"NPT coolant sensor. On my analog dash gauge, the temperature appears constant however the gauge is not overly sensitive. But when I view the log, I am seeing huge temperature swings. This is a shot of a logfile on a recent run, the engine was at full operating temperature and the road was a typical highway drive

The Y axis is Temperature, the X axis is seconds. Note how at 95-300 seconds the expected graphing displays, the changes in temperature ramps up and down as the thermostat opens. This is an expanded view of that area:

Now look at the time range between 626 and 807. Nowhere within this time range did I notice an abnormality in the analog temperature gauge or the running of the engine

Just as a comparison, I also run the typical GM Air Temperature Sensor. This is a chart of the two sensors, side by side, notice how the air temp displays the typical ramps up and down and the coolant sensor just goes wild

I originally thought this was just a bad sensor, but after replacing it twice and stills seeing the same results, it is something within the system.

The engine is an aluminum block Ford FE engine, 468ci, Borla ITB injected. I see the small changes in the sensor (less than 1 degree) around a transition point and just attribute this to the sensitivity of the potentiometer within the sensor. But I don't understand the large swings

Anyone have any ideas on what could be the issue?

For those using MegaLogViewer, I've attached my log file that these shots were taken from

Thanks

Paul

That does look noisy, and relatively low-resolution. But one thing to be aware of, often the auto-scaling of the graphs makes things look much worse than it really is. So, let's say your analog gauge reads from 100 - 240 degF. Try changing the scale manually of your graph to show the range 100 - 240 deg, your graph then looks a lot more "normal" to me.

Now the spikes downward are usually a sign of a wiring issue -- bad crimp, broken wire, worn insulation shorting to another signal, wrong ground pin used, etc. It interesting that it got worse in the middle of your trip -- was that a twisty road, or a bumpy freeway? While monitoring channels in the PE software, can you wiggle wires and cause the temperature to change? Does the value shown the software remain constant when the engine isn't running, or when it is running but you are connected to one of your spare sensors that is not measuring the changing coolant temp (say just in the air).

The temperature sensor is a variable resistance device, Does the PE-8400 have a built-in pull-up or pull-down resistor for that sensor, or did you have to add that externally in your wiring? If external, did you measure the actual resistance of the resistor you used? Since the resolution is so poor in the data, I wonder if a change in resistor value could improve the voltage range produced by the sensor, and with a different calibration produce better results.

A coolant temp sensors should be pretty rock steady, it normally only needs to be sampled at 1hz, since it changes so slowly.

David,

Thanks for your response, it is very helpful

1) I am using the viewer the Mfg. supplies and it 'automatically' sets the scale, base on the range in a selected time window. I need to become more familiar with MegaViewer and look again.

2) I was unaware of the indication from the downward spikes. I am going to do some wire tracing looking for any issues. The log file came from a relatively flat, straight road, but maybe some potholes introduced some abnormal vibration. I'll see if I can find any problem spots. I am going to try and log a static test on the sensor and vibrate different connections to see if I can reproduce the spikes.

3) The circuit does use a pull-up resistor however it is internal to the ECU

4) I was sampling some other data which required a little higher resolution and my ECU only allows one sample rate. Trying to do too much at the same time, I could change the sampling and just address this sensor to see what it reports under those conditions.

Talked at length with the Tech Support at Performance Electronics. They agree it is not normal, but can't come up with any ideas as to what may be causing it. At this point, all we can agree on is it isn't normal.

Wish your shop and mine were a little closer. Paso Robles and Saint Louis isn't an easy commute.

Paul

What were you doing at the time? If it was a steady speed and load I'd be more concerned than if it was driving around town or something like a fast country drive or track-day where the engine was under varying loads and rpm.

Part of the complications are the way the cooling system and thermostat work. The thermostat is reactive and opens when the temperature around it is higher than it's rating, allowing the heated coolant to pass into the radiator and allowing cooled water from the radiator to enter the engine - that cooled water could be only a little below the coolant in the head - or rather, by the time it passes thhrough the engine to the sensor it's only a little below it, so there will be relatively little difference. But, if the engine was lightly loaded, especially if the road speed was low, the coolant in the radiator could be close to ambient, and when that coolant enters the engine and reaches the sender, it could be much lower in temperature, sometimes to the point where the thermostat partially closes again, restricting the coolant flow through the engine and radiator, which gives the engine more time to heat up the coolant, opening the thermostat, and it continues.

I expect David has a LOT more knowledge than I, but I would suggest, if you have one spare, drilling a 1/4" hole, or two, in the thermostat to reduce the on-off action which should help stabilise the fluctuations, if David's suggestions don't work. The disadvantage is, of course, it will take longer for the engine to warm up.

Did you sort out the fuel pooling on the throttle butterlies and the lean/rich fluctuations with the throttles closed then opened?

Gord,

The run was interstate road driving - relatively smooth, flat, straight, 70mph. The engine was at temperature and did not display any problems. I only learned of this glitch when I downloaded the log files and started looking at them - I had made some changes in the Decel Fuel Cut Off and wanted to see up close what was going on with the fueling when I saw this coolant glitch

I haven't finalized the changes on my fuel pooling but I am seeing light at the end of the tunnel. I enabled DFCO which appears to be bringing it into control and better performance. Still working on the fine tuning of the setting - there is very little documentation on how to best set this.