Sale ends todayGet 30% off any course (excluding packages)

Ends in --- --- ---

Hey all,

I was wondering if anyone has any experience with Turbosmarts E-gates.

I'm finishing off building a Fiesta rallycar with Evo X running gear. The electronic gates make alot of sense for gravel rallying as we can request very little boost without soft springs, making it great for slippy conditions, rain, etc. Sometimes we will be wanting 25psi, other times 2psi.

It's not as critical in a awd as we should always have decent traction, but will be doing another turbo 2wd after this one.

Boost target will be constantly changing, I was told the E-gates can be slow to respond.

Can't find a heap of information on them, or anyone that has ran them in silimar applications.

Thanks alot!

I'm interested to know if anyone has them operating reliability in circuit or rally applications. I'm guessing water cooled diaphragm gate and 4 port solenoid is still the best weight/reliability compromise.

I spoke to a fella using one in circuit with no issues.

I think you're right, I have been worried about the reliability.

I have been assured that there is no reliability issues, but still a worry.

They can be slow to respond if their maximum duty cycle has been reduced to limit current. They still move slower than what is possible with a pneumatic (particularly co2) gate, but fast enough to achieve good boost response.

The water cooling is not optional, and in a rally application with an anti lag strategy I would try be mindful to give it the coolest water supply possible ie. radiator water outlet, not water post flowing through the engine or turbo, or if a charge cooler was being used incorporate the unit into that circuit. I would also try and integrate some airflow to the unit (particularly using it on a 4B11 with the exhaust on the firewall side of the engine).

They are quite bulky and heavy, so this needs to be considered when the manifold is designed. Outside of that, I have only got personal experience on an engine dyno and in a handful of drag cars, where they have worked fine. If I was building something for an identical application, my personal preference (especially if pneumatically paddle shifted), would be to do a pneumatic setup with a Turbosmart co2 style valve, and run a wastegate control strategy off the shift actuator tank to give you the same wide range of control pressures, but the electronic gate could also be used.

Thanks Nathan, great information.

Originally I thought of doing the co2 strategy with the paddle shift tank, but I eventually decided against paddle shift for this build. I had paddle shift in my other build which I was going to share accuators, I ran out of talent and wrote that car off so sold the kit.

Previous rally cars I have had were turbo fwd so it was critical for good boost control to limit wheel spin, this is where my thinking has come from.

I really think this car shouldn't have to much trouble getting the power down in most applications, it's a pretty standard jigga other than turbo and manifold.

I'm probably getting carried away and other thinking it. A pneumatic system should be well and truly suitable.

Air flow has been considered, I've put a large trans tunnel in it to get the air out.

It has the R5 style bonnet with the vents as well as a vent on the centre of the bonnet, it is a little weird but the comes as part of the Proto car kit. I was going to use the middle scoop to push air past the turbo, wastegate. I need to confirm the allowed bonnet openings in the Regs, but that's my idea.

As I know you're extremely knowledgeable, I have a question. Would thermocouples be suitable for measure engine bay temps, as well as other low temperature areas? I was going to test with different venting and monitor temps in different areas.

Thanks for your input, I think in my application the E-gate would probably be great, but maybe not worth the trouble.

Adrian,

K type thermocouples are very durable (as long as the first few inches are heat protected), but they are slower to respond than spec sheets tend to suggest. They're great for areas over 100c so as long as you're wanting to measure heat over time, understanding you may miss actual peaks.

If you're monitoring an areas you're confident will remain under 100c, then an open element air temp sensor can give you a bit more accurate reading, with quicker response to rapid temperature changes. You may still miss actual peaks, but you'll miss less than with a K type unit.

Thanks heaps Mike!!

Hi Mike,

Testing that I have done shows that a K-Type will react faster and see the spikes in temp compared to open element air temp sensors.

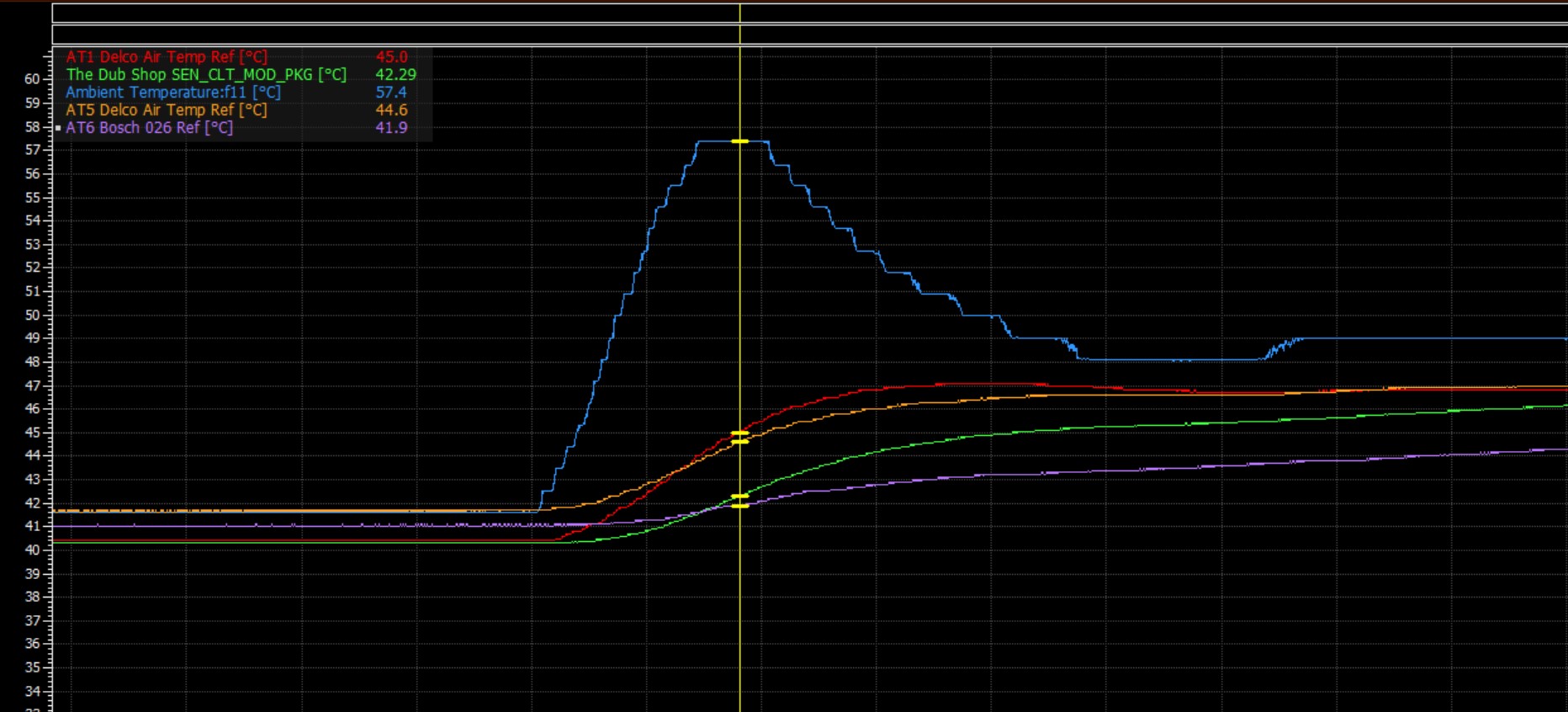

This test is from logging off of a MoTeC C185 doing a sensor calibration using our test oven. The Ambient Temp trace is using a K-Type sensor on a MoTeC TCA, the two Delco sensors are open tip and the Bosch is an enclosed tip. The oven has a spike when the heaters first turn on to step up the temperature which is captured by the TC, and partially by the Delco sensors.

Pizza Oven 40 to 50 by Stephen Dean, on Flickr

Pizza Oven 40 to 50 by Stephen Dean, on Flickr

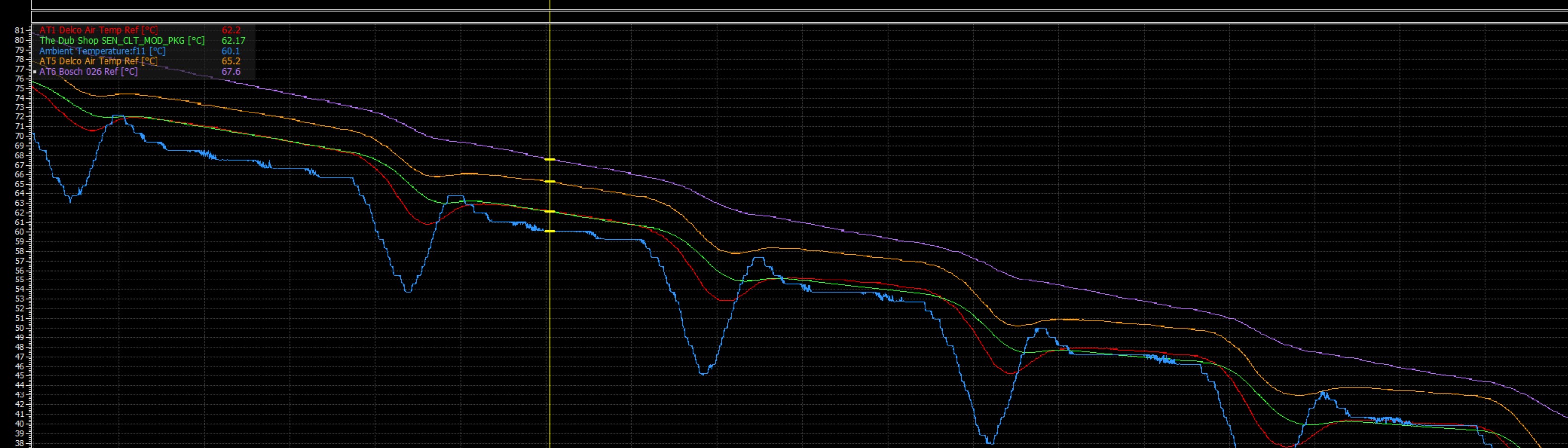

On going through the cool down process, it shows the same response behavior as the coolers turn on and off..

Pizza Oven cooling down by Stephen Dean, on Flickr

Pizza Oven cooling down by Stephen Dean, on Flickr

Yes, the open element air temp senders would be the way to go - check the ECU support and you'll possibly find a supported list and channel options.

Great data Stephen!

Without context, the caption "Pizza Oven cooling down" really made me wonder what the hell was going on hahahaha

Stephen,

It depends on which K type and which open element sensor you are testing, which is why I'm careful with my language and say things like it "can" be faster. You bring up a good point and the testing you performed is awesome. As long as the sensors are distributed in the over in a way that doesn't skew results, that sort of testing really helps choose which sensors you want to use. Well done!

Which k type were you testing and what was its operating range? Some of the thinner ones with more exposed tips are much quicker than others.

The Delco open air "fast acting" temp sensors are slow enough that I have people replace them before I tune their car, and I think your data is a good example of why. They miss so much data that protections based on high charge air temp can't really do their job. Unfortunately the naming seems to catch a lot of people out. The old packard style connectors also aren't the most reliable.

The low/medium speed DTM connector open air sensors from Link are a bit better and my usual go to for something cheap for basic projects, then there are more expensive options when speed is required and/or budget allows for it.