Think you need to spend $15,000 to get a decent 3D scanning setup? Think again! You can get started for just $1,000 or less. Here’s what you need to know.

3D scanning is becoming an essential tool for automotive fabricators and backyard mechanics. Think of your scanner as thousands of tiny tape measures working to deliver precise measurements and better-fitting parts a whole lot faster. But with so many options available, how do you choose the right scanner?

BEFORE YOU START

The metrics below are guidelines, not absolute rules. A scanner outside of the recommended ranges might still be more than capable for your needs. Numbers alone do not tell the full story, which is why it is crucial to understand what these metrics really mean before making a decision and purchasing, or even optimising your exsisting scanners settings for various projects.

Without further ado let's break down the most important scanning metrics, their real-world impact, and how to balance them to find the best scanner and scanner setup for your chosen projects/application.

In this article: Accuracy vs. Resolution: Understanding the Difference | Performance Factors Beyond Accuracy and Resolution | Choosing the Right 3D Scanner | Conclusion

Accuracy vs. Resolution: Understanding the Difference

Two of the most commonly compared metrics in 3D scanning are accuracy and resolution with a lot of people often mistaking them for the same thing, so it's important to clarify that these are independent variables.

Accuracy: How Close is the Digital Model to Reality?

Accuracy refers to how precisely the 3D digital model represents the actual physical object. It is measured as the deviation between the scanned points and the real-world counterpart. Higher accuracy results in minimal deviation, ensuring a closer match to the original dimensions.

However, advertised accuracy specifications often state an "up to" value—such as "up to 0.1mm"—which represents the best-case scenario. Real-world accuracy depends on factors like the object being scanned, scanning conditions, and the technique used. Even two scanners with identical accuracy ratings may perform differently in practice.

Since accuracy is also influenced by the scan size, it is sometimes expressed as a percentage of error per metre. Larger scans tend to accumulate more error, reducing overall accuracy. High-end scanners achieve accuracy as fine as 2 to 30 microns (for reference, a human hair is approximately 70 microns thick). However, such scanners are primarily used for metrology applications, rather than for motorsport or mechanical design, and come with significantly higher costs.

For most motorsport applications, scanners with 0.05mm to 0.1mm accuracy are sufficient. To put this into perspective, 0.1mm is approximately four-thousandths of an inch, making it suitable for tasks such as component fitting and design validation. While higher accuracy is necessary for precision-critical parts, the reality is that 0.1mm accuracy is great for most people.

As mentioned earlier, it's important to note that this is just one metric, and even though 0.1mm is the higher end of our recommended target range here, that doesn't mean anything over that figure might not be good enough for your own application.

Resolution: The Level of Detail in a Scan

Resolution defines the distance between two adjacent data points in a scan, also known as point distance. A smaller point distance results in more detailed scans, but also increases file size and processing requirements. More data points mean a denser point cloud or finer mesh, providing greater surface detail at the cost of longer scan times and higher computational load.

Most professional-grade scanners operate within a resolution range of 0.1mm to 0.2mm, while smartphone-based scanners may have resolutions in the millimetre range. The key takeaway is that accuracy and resolution are not directly correlated—a scanner can have high accuracy with low resolution, or vice versa. This means that selecting the right scanner involves balancing these two factors based on project requirements.

For example, scanning a highly detailed object such as a textured surface or an intricate engine component requires a high-resolution scanner to capture fine details. On the other hand, scanning larger, simpler objects like vehicle exteriors benefits more from a larger field of view and does not require extreme resolution.

Frame Rate Vs Measuring Rate

While accuracy and resolution determine scan quality, they do not fully define a scanner's efficiency. Several other factors influence the practicality and usability of a scanner for real-world applications.

Frame Rate and Measuring Rate

Frame rate, measured in frames per second (FPS), and measuring rate, expressed in measurements per second, dictate the speed of data collection. A higher frame rate allows for faster scans, but it requires the computer processing the data to keep up. If the processing speed is insufficient, some scanners automatically lower their frame rate, leading to slower and less smooth operation.

Field of View and Depth of Field

The field of view (FOV) and depth of field (DOF) determine how much area a scanner captures in a single scan. These values define the volume of space within which the scanner can collect data.

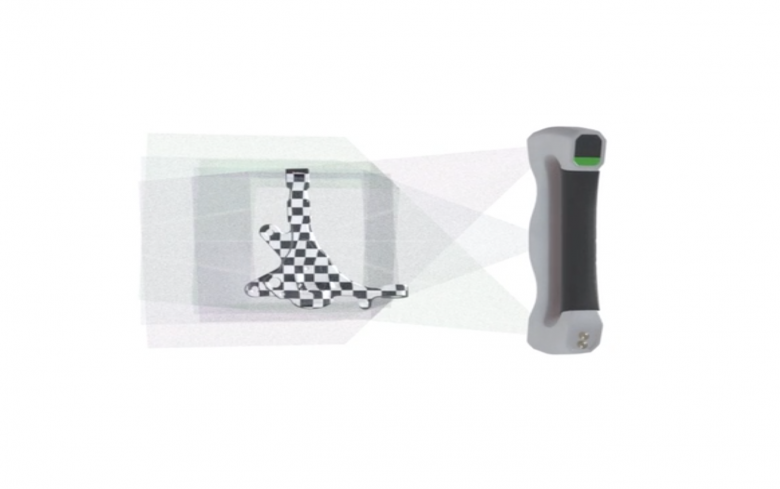

Most 3D scanners function based on triangulation, using a projector and two cameras at a fixed distance apart. The cameras observe how projected light interacts with the object’s surface to determine its geometry. This creates an imaginary pyramid-shaped capture area where the scanner can record data.

-

Field of View (FOV): The cross-sectional area of the scan range. The FOV is usually larger at greater distances from the scanner.

-

Depth of Field (DOF): The range within which the scanner can effectively capture data.

A larger field of view improves scanning efficiency, especially for bigger objects like vehicle exteriors or chassis components. However, scanners with large FOVs typically trade off resolution, meaning they capture less fine detail. Some high-end scanners allow for adjustable scan ranges, accommodating different object sizes and scanning conditions.

Choosing the Right 3D Scanner

Selecting a 3D scanner involves assessing the trade-offs between accuracy, resolution, speed, and field of view. The best choice depends on the intended use:

-

For high-precision parts like bearing carriers or engine bores: Look for a high-accuracy (≤0.1mm), high-resolution (≤0.2mm) scanner.

-

For large object scanning like fender panels or engine bays: A scanner with a wider field of view and moderate resolution (≤0.5mm) will be more efficient, even if accuracy is slightly lower.

-

For general motorsport applications: A balance between accuracy, resolution, (≤0.2mm for both) and speed (which includes our scanner's software quality) ensures practical usability.

So, which scanner should I choose?

We tested a few different scanners while creating the Practical 3D Scanning Course and have a few recommendations depending on your budget:

Under $1,000 USD

Under $5,000 USD

~$10,000 USD

- Peel3d - Peel 3 (the scanner we use an HPA)

- Shining3D Einscan HX or Pro HD

Over $20,000 USD

Conclusion

The best 3D scanner is not necessarily the most expensive one, it’s the one that fits the requirements of the job. A high-accuracy, high-resolution scanner with a small field of view might be less effective for scanning large areas compared to a lower-cost, lower-accuracy scanner with a larger field of view. Factors like scanner weight, portability and wireless capability may also be important depending on your own personal application. Before investing in a scanner, carefully evaluate its specifications and how they align with your intended use case the best you can, but ultimately getting started with something to gain experience, even if it's not the 'perfect scanner you will keep forever' is still a valuable and worthy goal.

Now you have a better understanding of these performance metrics, you are in a better position to make informed decisions on your 3D scanner purchase and might enjoy watching this budget 3D scanner webinar comparison. The next (and arguably harder!) step is learning how to work with your scan data, which also benefits from some basic 3D modelling skills, both of which you can start learning instantly via HPA's online course material.