When it comes to choosing a turbocharger, there are so many options out there that you might think it easier to crawl into a corner and hide. There are so many variables that can affect the way a turbocharger will perform. Fear not, we’re here to help break down what can be a daunting process.

In this article: Getting It Wrong | All The Boost? | Lag vs Boost Threshold | Turbocharger Performance Considerations | How To Read Compressor Maps | Airflow vs Power | Mass Airflow to Power Rule | Turbo Selection | Conclusion

Choosing The WRONG Turbocharger

Before we get into the nuts and bolts of choosing the correct turbocharger, let’s discuss what happens if you get it wrong. If you choose a turbocharger that is too large for your application, you will most likely have a car with no low RPM performance. It takes a certain amount of exhaust gas energy to get the turbocharger moving and if the turbocharger is too big, your application won’t be able to provide this. On the other hand, if you choose a turbocharger that is too small, you will get outstanding boost at low RPM but it will choke the airflow through the engine at high RPM.

Boost Pressure - Largely Irrelevant

As well as teaching you factors that are important to take into consideration when choosing a turbo, let’s discuss something that has little bearing whatsoever, boost pressure. Don’t get us wrong, you do need to know how much boost your engine is running but there is a lot more to how much power your engine is likely to make than just boost pressure.

Let’s look at an example. If you were running 15 psi of boost using a Garrett GT3076 and then swapped it out for a Garrett GT42 which is a much bigger turbocharger, you will get a hugely different amount of power from the exact same engine. Equally, if you modify your engine but keep the same turbocharger and run the same boost, you will have an engine that produces more power. Think of boost pressure as the amount of restriction that the engine itself poses to airflow. There is not a direct correlation between boost pressure and power.

Lag vs Boost Threshold - Which is which?

Two terms that are often used incorrectly are lag and boost threshold. Let’s clarify these terms. Boost threshold is the location in the rev range where full boost is achieved. Once you get above the boost threshold, if you take your foot off the throttle then put it back on and go straight back to full throttle, the turbo can’t instantly jump back to full boost. This is lag and it exists because the rotating assembly inside the turbocharger and the exhaust wheel are heavy and require a certain amount of inertia to get back to full boost.

What Affects Your Turbocharger’s Performance?

- Compressor and turbine wheel size - The more air you want to move, the bigger these will be. Having said this, nowadays with advances in aerodynamics and the materials used, it is hard to draw a strict correlation between size and power.

- Billet vs cast compressor wheel - Billet wheels look great but they don’t necessarily improve performance. Manufacturers use them because it is much easier to produce runs of billet wheels which allows multiple designs to be tested much faster than cast wheels. Billet wheels are generally stronger which will benefit those running very high boost levels. Another advantage that comes with this is that the hub where the wheel bolts onto the shaft can be thinner which allows more airflow. It is important to note that although manufacturers are turning to billet, a cast wheel of the same profile can be manufactured. Billet is not the be-all and end-all.

- Turbine wheel material - Anything that can be done to reduce the weight of this will help overcome its inertia and get it spooled up and producing boost pressure. In the earlier days of turbocharging, ceramic was used. This turned out to be somewhat disastrous as they were prone to falling off with high boost when they bonded to the steel shaft of the turbocharger. BorgWarner and Garrett are now using, respectively, Gamma-Ti and MAR-M, basically just lighter materials. MAR-M can also support higher operating temperatures with continuous use up to 1050 degrees C.

- Twin scroll vs single scroll turbine housings - Although it is difficult to get a comparison where this is the only thing that has changed, in general, you will end up with a better low RPM boost response.

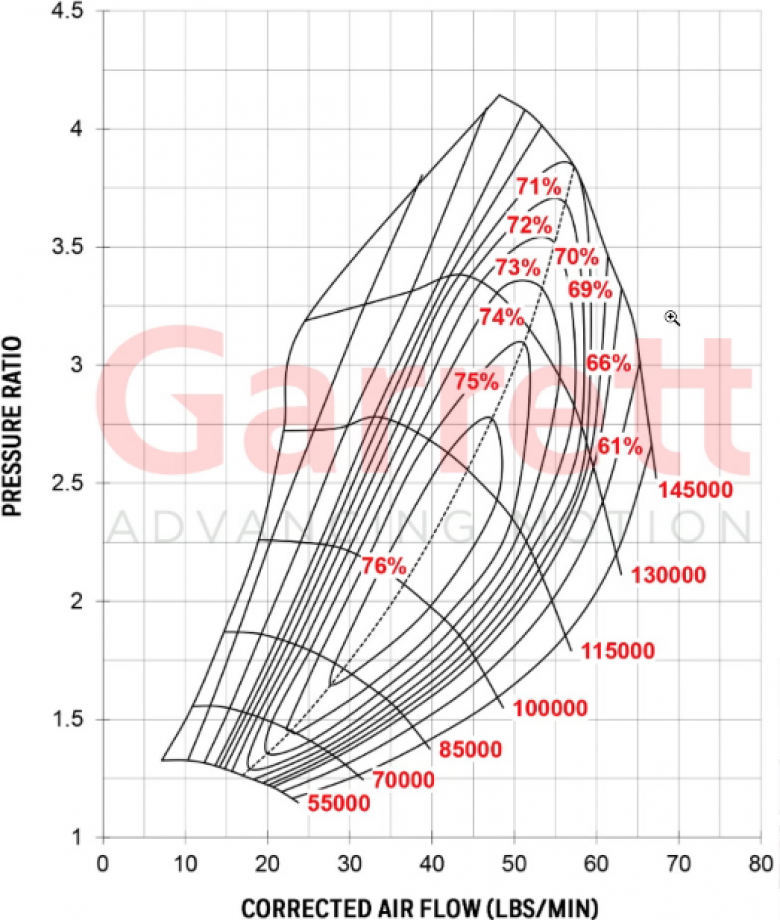

How To Read Your Compressor Map

It is important to be able to read a compressor map and understand what all the numbers mean. The below graph is what you will see from most manufacturers. On the vertical axis is the pressure ratio. This is the compressor outlet pressure divided by the compressor inlet pressure. For example, if you are running 200 kPa of boost pressure (outlet) and have 100 kPa of atmospheric pressure (inlet) then you would have a pressure ratio of 2. On the horizontal axis is corrected airflow in pounds per minute which is how much air the turbocharger can move.

Moving onto the map itself. The line on the left side is the surge limit. You don’t want to be operating to the left of this line as you will end up damaging components. It also will not be a pleasant experience driving a car that is surging. The line on the right side is the choke limit. This is the point at which the efficiency of the turbocharger plummets and instead of moving air, it is just pumping heat into the compressor outlet air. As you might be able to guess, you want to be operating between the surge and choke limits.

Now let’s look at the islands in the middle of this map. For example, in the middle island, the compressor is 76% efficient. The worse the efficiency of the compressor, the more heat is going to be added to the air. This means that the intercooler will have to work harder and the compressor will require more energy to move the air.

Lastly, the lines running across the map are the turbine speed lines. The values for this are on the right-hand side and tell you how fast the turbine is operating.

Mass Airflow to Power Rule

As a general rule of thumb, you will need about 9.5 to 10.5 pounds of airflow per minute for every 100 horsepower you want to make. This is not completely reliable, however. To get the required turbo flow, you need to be operating in the correct pressure ratio.

Other factors to do with engine design can also affect the turbo’s ability to make the power it is capable of. For example, if you’re operating on a low octane pump gas, you will almost certainly be knock limited. This is where you increase the boost pressure and advance the ignition timing to the point of detonation. Now, of course, you can’t operate your engine under these conditions so you will need to retard the timing or reduce boost pressure. As you can probably guess, this limits the power that the turbocharger can produce.

Selecting Your Turbocharger

Alright, now that you’ve got all the background information, let's choose a turbo!

One of the easiest options here is to leave this to a performance workshop that is familiar with your car. This isn’t a bad option if you live somewhere with specialists who know your model of car inside and out. Especially if you have a popular car, for example with the Subaru WRX STi range, turbo setups have been tried and tested to death and specialist workshops will have a good database of what works. Of course, if everyone went with this option, there would be no need for this article and you won’t be involved in the process yourself. Where’s the fun in that!?

Alternatively, you can do your own research on the internet. This can be a minefield, with the potential to waste a lot of time and be sent on a wild goose chase. Be prepared to find a lot of conflicting information. If you’re going to go with this option, look for multiple results that back up the same idea so you can be confident it is correct. Enthusiast forums are a good place to check out.

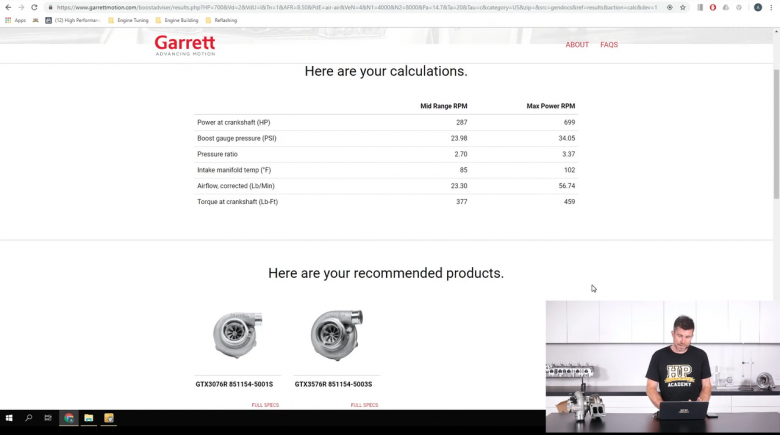

The above two options can work well if you’re dealing with a popular platform but not so well if you’re dealing with something that isn’t commonly modified. If this is the situation you’re in, or if you just want a more advanced way of choosing a turbo, turbo sizing tools do a great job. We’ll discuss two options here, starting with the simpler of the two, Garrett’s Boost Adviser. This program requires you to enter crank horsepower, engine capacity, whether you’re installing 1 or 2 turbochargers, fuel type, intercooler type, number of valves, mid-range and peak RPM, altitude and temperature. As you can see, there are a few variables required but nothing too complex.

Using the information you have input, the Boost Adviser then spits out some recommendations. As you can see, in this case, there are two. Garrett has made a bit of a tradeoff with their Boost Adviser, between how much information you, the user, are required to enter and how accurate the results are going to be. The more information that is asked of the user, the more accurate the results will be, but also the less likely the user is to be able to provide the information.

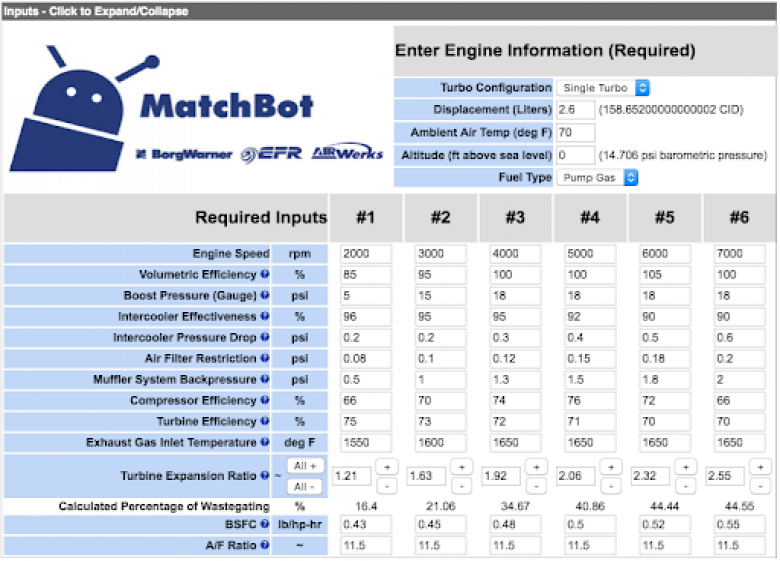

In comparison, let’s have a look at BorgWarner’s MatchBot. This is more complex and requires you to input a lot more information. There is also a lot more room for error. We’re not going to take you through all aspects of MatchBot in this article as it would rapidly turn into a novel. If you want to find out more, BorgWarner has a YouTube series of videos on how to use it.

To start with, at the top is some engine information you need to enter. Below that are 6 set points that will be plotted on your compressor and turbine map. You can change the RPM for each of these setpoints if required. With the other values, you may not know them exactly for your engine. This is where BorgWarner helps you out a bit. If you hover over the ? beside each value, they give you an idea of what the values should be. The more accurate you can be with your values, the better the MatchBot will work. However, even their default values are still a great starting point.

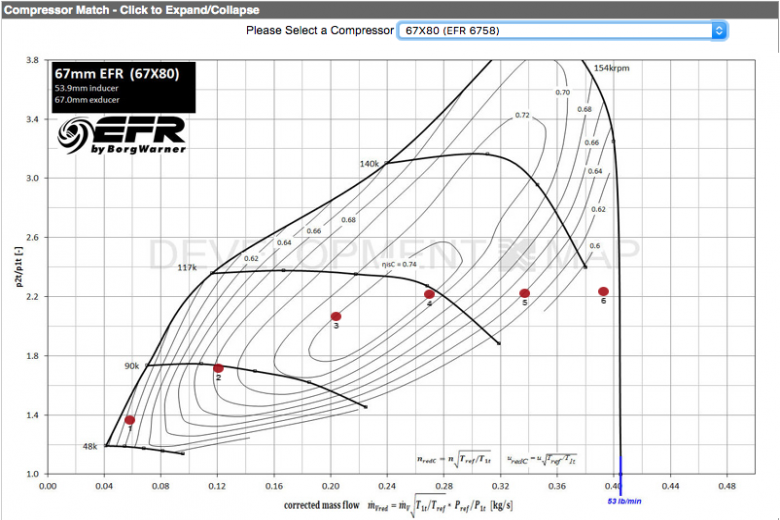

Once you input the above values, you can choose a range of compressor maps to see what suits the points that you’ve plotted which are displayed as red dots. First, let’s have a look at a 6758 EFR turbocharger. As you can see, everything is within the surge line however point 6 is past the choke line. As previously discussed, this is not something you want so this turbo will not work.

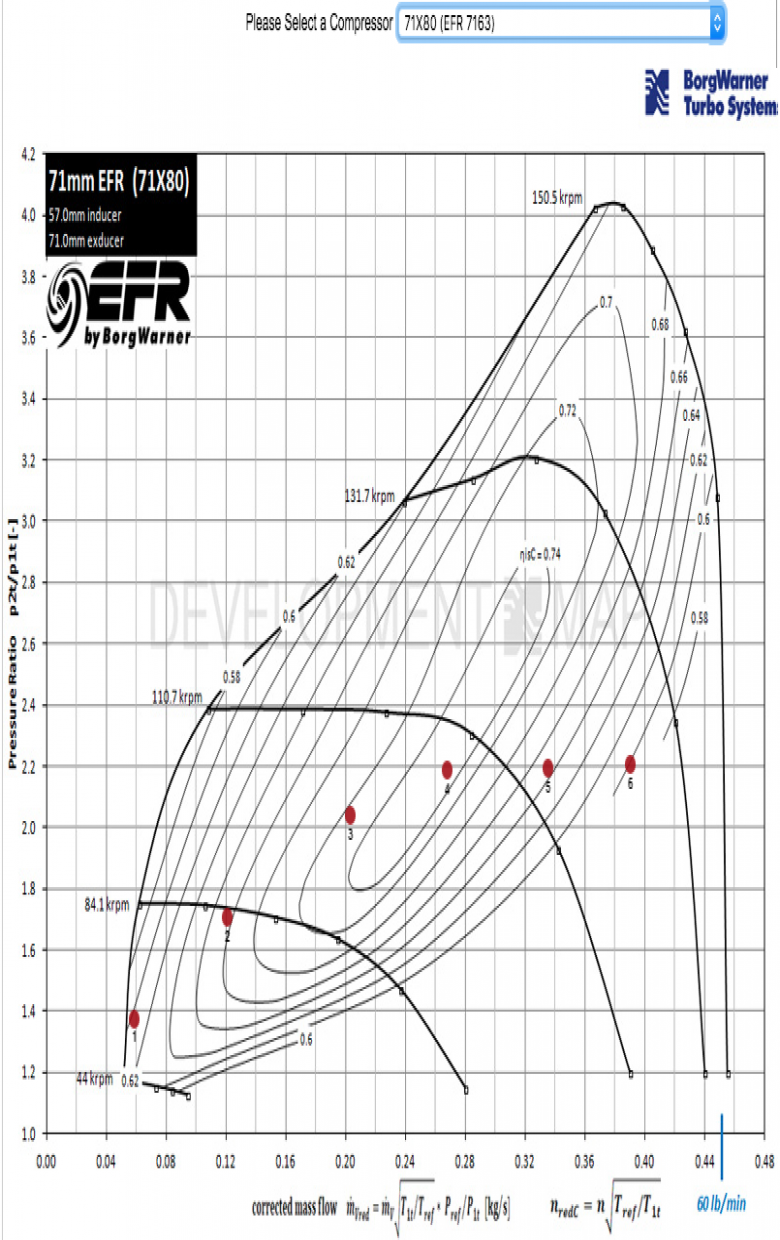

Next, we’ll try the 7163 EFR. As you can see, the turbo will be pushed hard at 7000 RPM but other than that, you will be operating through an efficient area of the map and are still clear of the surge line. This turbocharger will work well for the values entered. You would now take the compressor efficiency values and enter then back into the inputs table in the applicable fields.

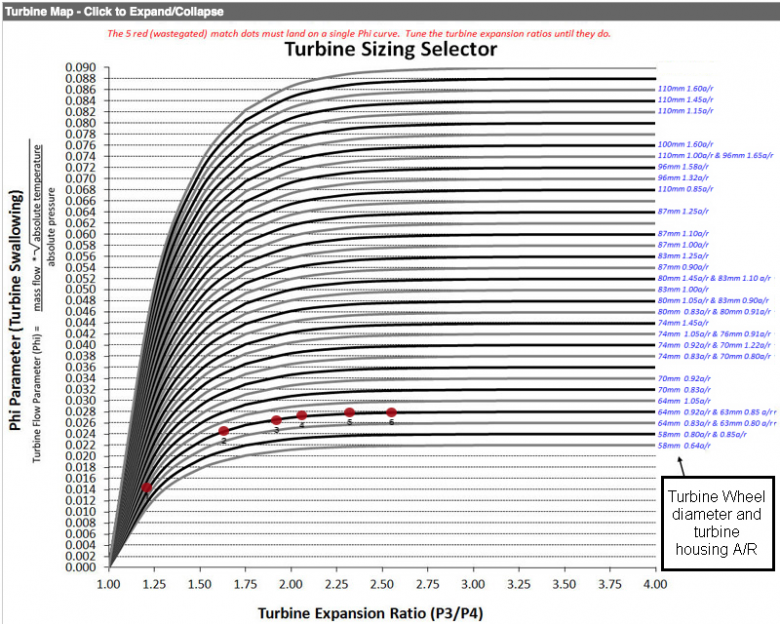

Next, MatchBot helps you to size your turbine housing and turbo wheel as well as giving you an idea of what sort of boost response is going to be realistic. What you need to do is manipulate your turbine expansion ratio numbers (in the first window), to make all of your setpoints sit on one line. If you follow the line across that all the setpoints are sitting on, you’ll see that this is for a 63 millimetre 0.5 A/R exhaust housing. So this is what you would want to use with a 71 millimetre compressor wheel.

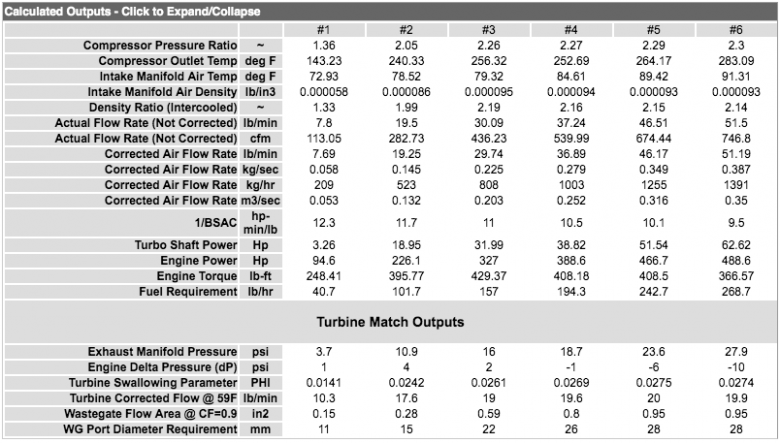

Just in case that wasn’t enough detail for you, MatchBot gives you a value of calculated outputs for various parameters. One of the most important things to take note of here is exhaust manifold pressure. The problem with running a small turbocharger and pushing it hard is that at high RPM in particular, the turbine side of the turbocharger starts to become a restriction. At 7000 RPM, there is 18 psi of boost pressure in the inlet manifold. To achieve that, you will end up with 28 psi in the exhaust manifold. The engine can’t get rid of the exhaust gas which reduces the volumetric efficiency. In reality, what you will really need to do is reassess what the actual volumetric efficiency will be. We had entered 100%, perhaps it will be more like 90%. One way to remove some of this restriction is to move to a greater AR exhaust housing.

Since most people will be taking an educated guess with the values being input into MatchBot, if you are serious about getting the most out of your turbo, it is a good idea to add some sensors so you can data log and validate the performance. That will also mean you will have solid data to work from if you want to upgrade your turbocharger at a later point. Consider adding an exhaust manifold pressure sensor. This will tell you the ratio between turbine inlet pressure and inlet manifold pressure. The lower that ratio is, the more performance you will get from your turbocharger. Also useful would be a compressor or turbo speed sensor. This will let you know if you’re getting close to the critical speed when you’re pushing your turbocharger hard. Lastly, you might consider an air temperature sensor so you can measure the temperature coming out of your turbocharger which will give you data on how efficient your intercooler is.

Conclusion

As you can see, there are a lot of factors to consider when it comes to choosing a turbocharger. Hopefully, we’ve shown you that while there is a lot to consider, it isn’t as daunting as it first seems. Especially with the help of your local performance workshop, enthusiast forums, tools like MatchBot and of course, HPA, there is always plenty of help at hand.