Did you know solder is NEVER used in a professional motorsport wiring harness? Did you know that a properly executed crimp joint is actually stronger than the base wire?

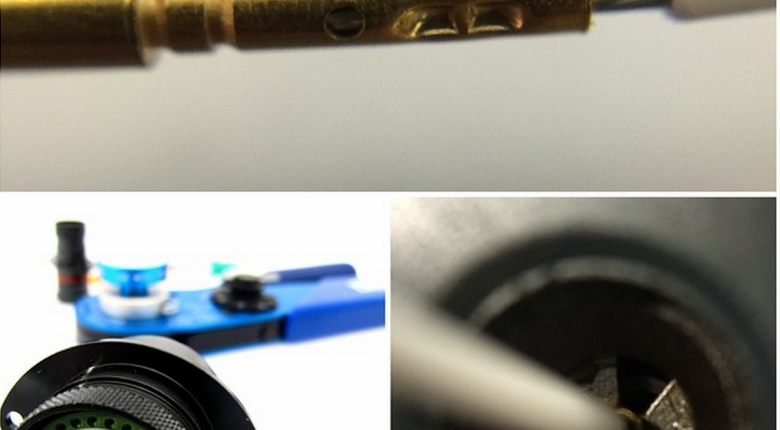

That means if you pull on a crimped joint until it fails, the conductor strands will break before the crimp fails. Doing it right starts with the correct materials - In this case a Deutsch Autosport79 position bulkhead connector, gold plated terminals and 22 AWG Tefzel wire.

Just as important are the correct tools - In this case a DMC crimp tool with the correct positioner to suit the terminals used. A proper crimp starts with correctly stripping the insulation without damaging the conductor strands underneath. This is harder than it sounds with the tough insulation on mil-spec wire. The insulation should be stripped far enough that 1-2 mm of bare conductor is left exposed when the wire is fully seated in the terminal (as shown).

This makes it easy to confirm the wire is fully engaged in the terminal and eliminates any potential stress on the conductor from the insulation butting against the back of the terminal. Correct engagement can also be confirmed by checking the conductor is visible in the circular inspection window in the terminal. Next, the crimp can be performed. The DMC crimp tools use a set of mechanical jaws to precisely crimp the terminal in exactly the right place and to exactly the right depth as over-crimping a terminal is just as bad as under-crimping it. Now let's talk about solder.

Correctly applied, a solder joint can be strong and offer good conductivity, but a solder joint is also brittle and is prone to failure under continual vibration - Exactly the conditions we can expect in the harsh motorsport environment. This is why we avoid solder joints at all cost in situations where reliability is critical.

If you're keen to learn more about wiring, check out our wiring fundamentals course.