If you are tuning a factory LS engine using the technique of reflashing, idle speed tuning may not be something you need to give too much consideration to. When you’ve got a standard engine, provided your mass airflow sensor calibration is correct, you should be set and the stock idle configuration shouldn't need any work. If however, you start making more serious modifications, your idle speed tuning will suffer. Read on to find out how to rectify this issue and have your GM vehicle idling perfectly, no matter whether it’s hot enough to boil an egg on your bonnet, or cold enough to freeze that egg solid.

In this article: Be Realistic | Ensure Your Tables Are Correct | Base Airflow | Adaptive Idle Control | Conclusion

Be Realistic With Your Target Idle Speed

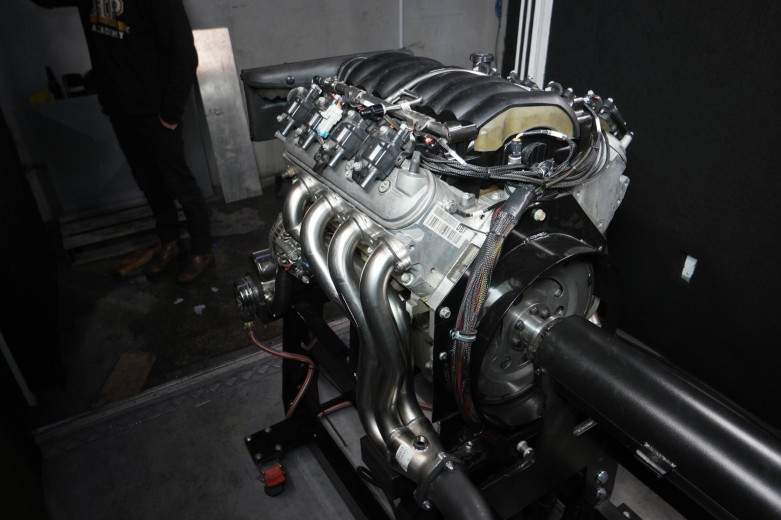

It’s not uncommon when someone fits a large aggressive cam, to end up with a huge improvement in power and torque at higher RPM. However there are no free lunches, and the additional lift, duration and overlap that gives those mid to high rpm gains can significantly reduce the volumetric efficiency of the engine down in the low RPM regions. This leaves you with a car that idles very poorly and leaves you scratching your head thinking “where did I go wrong?!” This is why it is important to put a lot of effort into idle tuning in order to replicate the quality you would expect from a factory car.

With a stock LS, the factory idle speed will be around 550 - 600 RPM. When you modify that engine and fit a large aggressive cam, you need to consider what RPM that engine is now going to want to idle at. You need to make sure your target idle speed is sensible. This depends on the size of your cam, the lift, and the duration. To give you an idea, if you’re in the 240 degrees, 50 thou duration area, you’re likely to need an idle speed of around 800 - 850 RPM. If you aren’t sensible with this target, you’re throwing away time trying to get the engine to do something it isn’t comfortable with.

If you’re dealing with an automatic transmission with a factory torque converter this can throw you a curveball. The factory torque converter is designed for the factory cam and idle speed. When the car is in drive, if you take your foot off the brake, the car can be pushy and drive forward so you do need to bear that in mind. If you aren’t comfortable with this, you can consider a high stall converter which is better suited to an aggressive cam.

Ensure Your Fuel and Ignition Tables Are Correct

In order to tune your idle speed control, one of the first places you need to start is getting your fuel and ignition tables correct. Too often, both with reflashing and standalone platforms, tuners try to fix idling issues by playing around with the idle speed parameters when the real issue is simply that the air-fuel ratio is too lean and the engine is just not happy idling like that. This same issue could also be caused if your air-fuel ratio is too rich and you’ve got large steps in your ignition table.

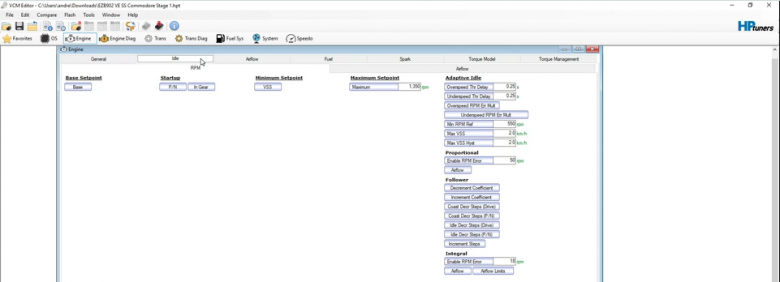

Starting with your idle tab below, this is obviously where you’ll be doing a lot of your tuning. Here you can see you have two tabs, RPM and airflow.

Clicking on the base set-point brings up the below table. This shows your idle targets depending on whether you’re in gear or in park/neutral and what your engine coolant temperature is. You can see that when the engine is cold, 850 RPM is the target. The decreases to 550 RPM as the engine heats up. We previously mentioned that with an aggressive cam, you may need to be idling at 750 - 850 in the normal operating area. In this case, you would also increase the colder areas, maybe not by as much as 300 RPM but you might want to go from 850 RPM to 950 RPM.

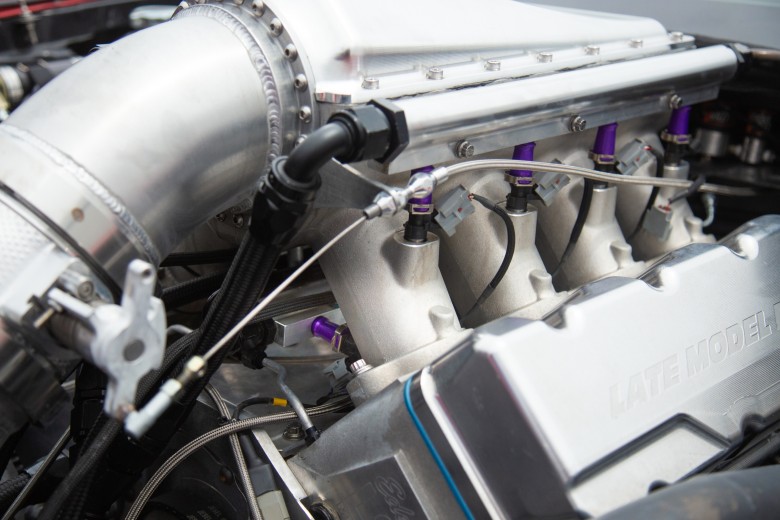

Moving across, you have your idle airflow tab. The first parameter we will look at in the effective area is percentage max. There is a lot of confusion around this, even from people who are familiar with tuning GM vehicles. You don’t need to touch this number when you are dealing with a stock engine with a stock cam. When you are tuning an engine with an aggressive cam, especially when it’s cold, you can make all other changes under the sun but if you don’t change this parameter, you won’t get enough air bypass through the throttle body in order to get the engine to idle when it’s cold. You will likely find that the throttle position flat lines at around 25%.

With a stock engine, percentage max is set to a little below 2% to limit the maximum amount of throttle opening usable. Some tuners resort to drilling holes through the throttle plate in order to bypass more air through the throttle when it’s closed. Don’t be one of those people. Not only is this an ugly but it can cause problems down the line, and it's completely unnecessary. Instead, you can just change the percentage max to allow more throttle opening during idle control. The change you make here will depend on the size of your cam. With a really aggressive cam, you may need to increase it to 4% to allow a larger range of throttle opening in order to bypass more air through. If you increase it and find that your throttle position still flat lines at around 25%, you will simply need to keep increasing it a little further. Keep in mind that you will want just enough to have your engine idling smoothly when cold so don’t go making bulk changes here.

Base Running Airflow Settings

Next, under base running airflow, you have your airflow final minimum table. This shows the airflow minimum relative to what gear you’re in and your idle airflow RPM. This is telling the engine what airflow is predicted to be required for idle which sets the particular throttle position that will be used. Just like with your idle target speed table, you won’t need to make changes to this table with a stock engine however when you have an aggressive cam, a lot more airflow will be required. For example, around the 600 - 1000 RPM area, those numbers will need to be picked up significantly, possibly by as much as 50%.

This table could look a little different depending on what engine control module and car you’re working with. For example, below is the equivalent graph from a Gen 3 LS1. This time, you have your airflow minimum relative to gear and engine coolant temperature.

From here, you can use the histogram feature in your VCM scanner software to help you fill this table in and get it right. To do this, you need to set up a histogram with the same breakpoints as this table. As you can see in the below image there are a few parameters you can change around. Here, we’ve got it set to log mass airflow, being the mass of air required for the engine to idle. We’re then using engine coolant temperature on our horizontal axis and have copied across the values from our idle airflow table.

The idea when you get to this point is that you’ve got the engine running well but the base running airflow tables may not be correct. Now that you’ve got your table set up, you can start recording data. Ideally, you want to start this from stone cold. The climate you live in will determine how low down in the table you will be able to collect data. As the histogram fills in, it will average the values and give a great set of data that you will be able to copy straight back into your base running airflow table. You can then use the trend to extrapolate into areas of the table that you were unable to gather data from.

Depending on how particular you want to be and how much time you have, to get data when the car is in gear and in park/neutral, you have two options. You can either gather data while the car is in park/neutral and then add one or two to the result for the in gear row. Alternatively, you can run one and then come back the next day when the car is stone cold again and run the other to get more accurate results.

Pro tip: add one or two grams to the numbers from the histogram. This is to allow for the little drop in RPM as you come back to idle and will mean that the idle will be held and won’t drop below your target.

Adaptive Idle Control

Adaptive idle control is used to control the idle speed using the ignition timing. You can access this by clicking the spark and then the advanced tab. Under adaptive spark control, you have parameters for overspeed (above your RPM target) and underspeed (below your RPM target). Under each, you can select values for park/neutral and in gear. If you open up the overspeed table, you will see that you have an error in RPM from your idle target as the parameter. As your error increases and you get further above your idle speed, spark advance is removed.

Your underspeed table is the exact opposite, as your idle speed drops below your target, spark advance is added.

As with everything else in this article, these tables work well as is for a stock engine but can be a little overbearing with an aggressive cam. If you need to dial them back, a good way of doing this is to multiply the whole table by half and go from there.

Conclusion

As you can see, there is nothing overly complicated about idle tuning and it is an essential aspect to take care of for both enjoyment and performance. No one wants to be nursing their car in order to keep it idling at a target that is far too low, just as no one likes a job half done when the time isn't taken to set it up correctly especially if you're not driving a drag car that is essentially only run for minutes a few times a month.

If you want to learn more about idle tuning as well as how to tune your fuel and ignition before you reach this step, start with a free lesson.